PET Series is highly energy-serving. With our Standard Injection Molding Machine’s new driving system, the motor will stop at the cooling stage to save energy and can provide higher injection speed and accuracy. It has a wide range of clamping forces (1680-2680)KN, and the driving system is hydraulic with a servo motor type. This series is applied widely in food and beverage packaging, necessity products, home appliances, electrical components, and automotive parts.

* PLC Controller

The MG series use the latest control technology. This high-performance control system provides excellent communication between the injection molding machine and the operator. The uniform operating concept and logical, clear structure of the functions make machine operation easy and user-oriented.

* PET Injection Unit

Optimized special L/D 25:1 screw, requiring a more extended machine base, is driven by a high output motor for dramatically improving the plasticizing of the PET material to ensure the quality of the PET preform. Increased ejector force consistently ensures the finished parts are ejected automatically.

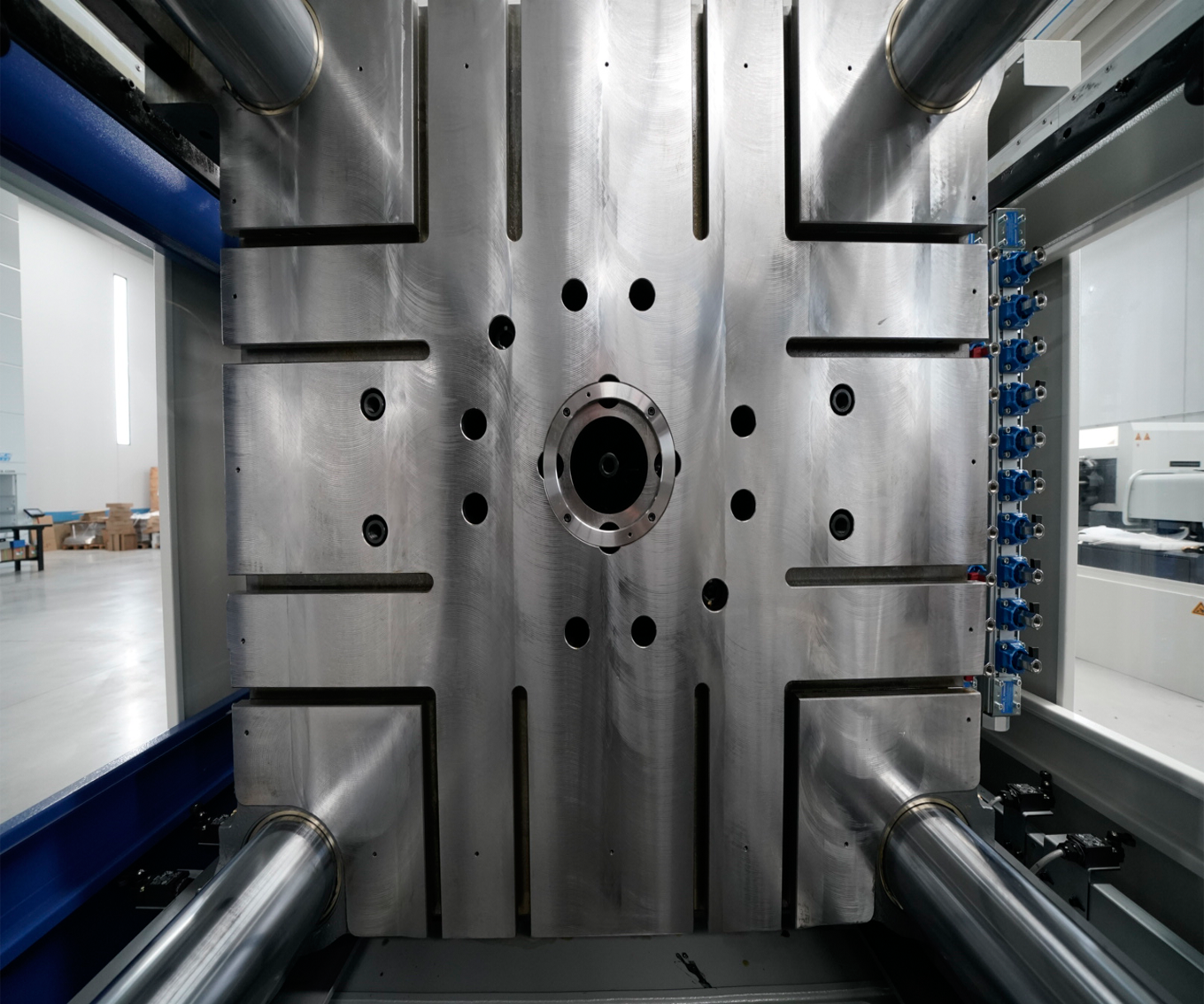

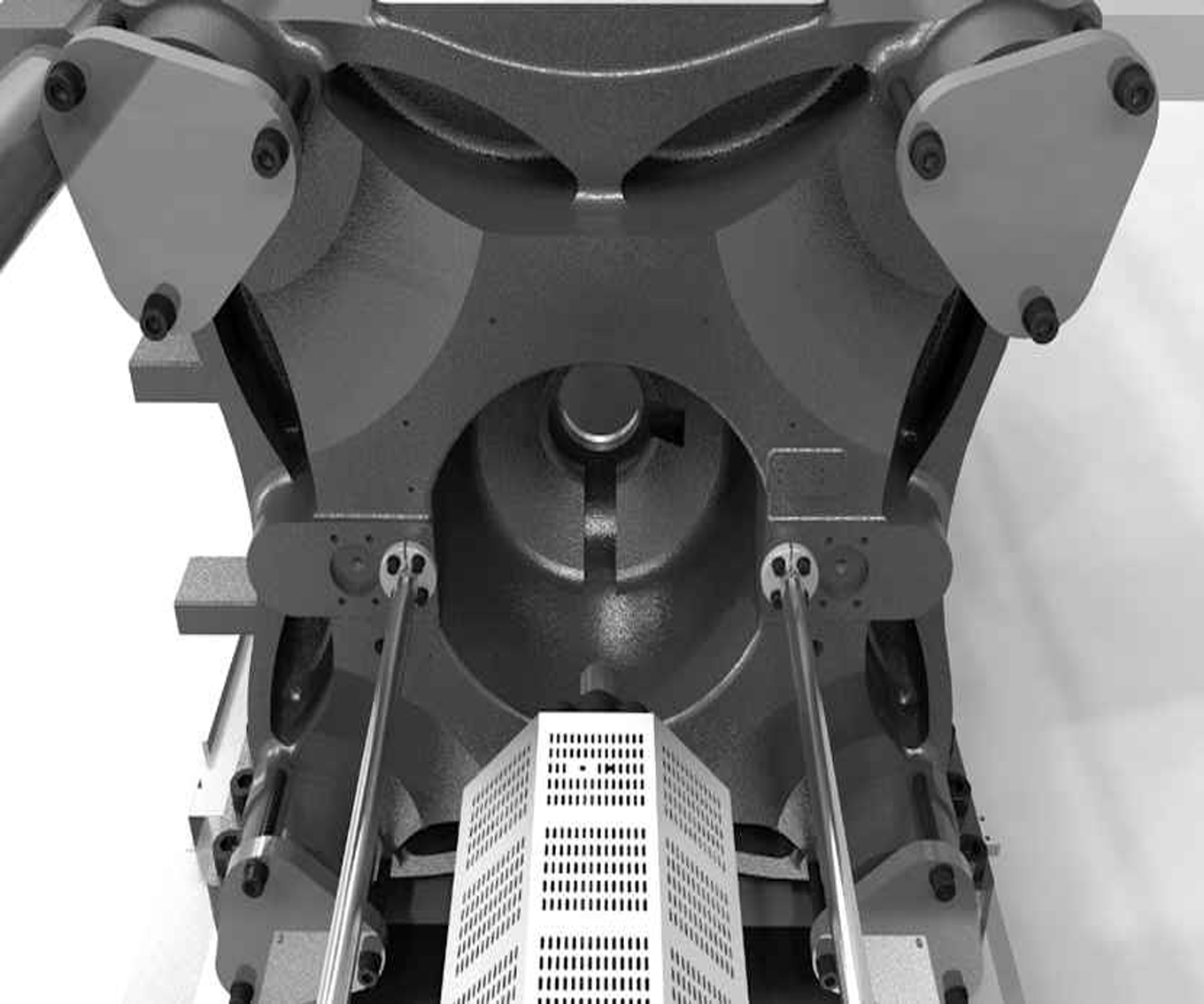

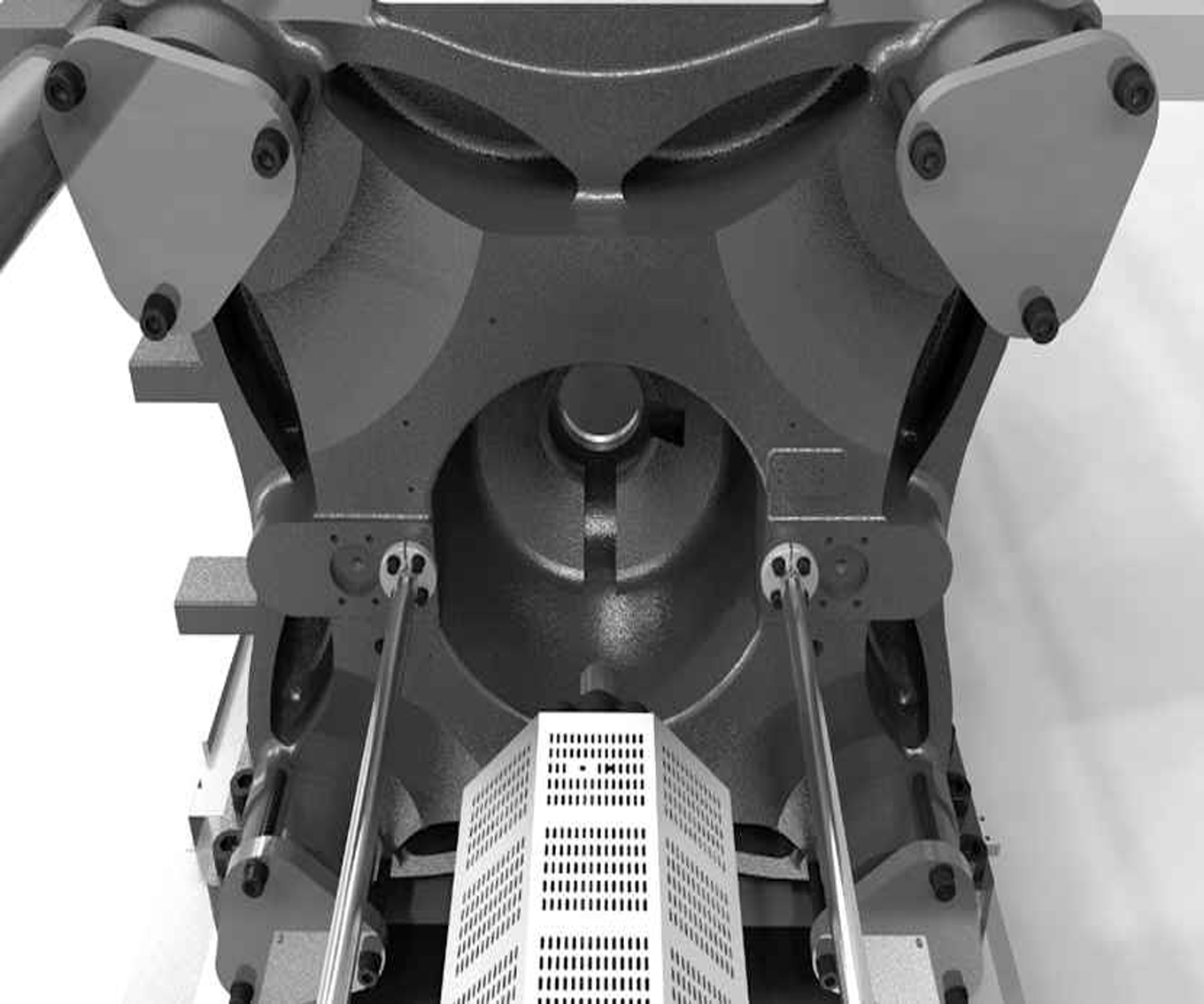

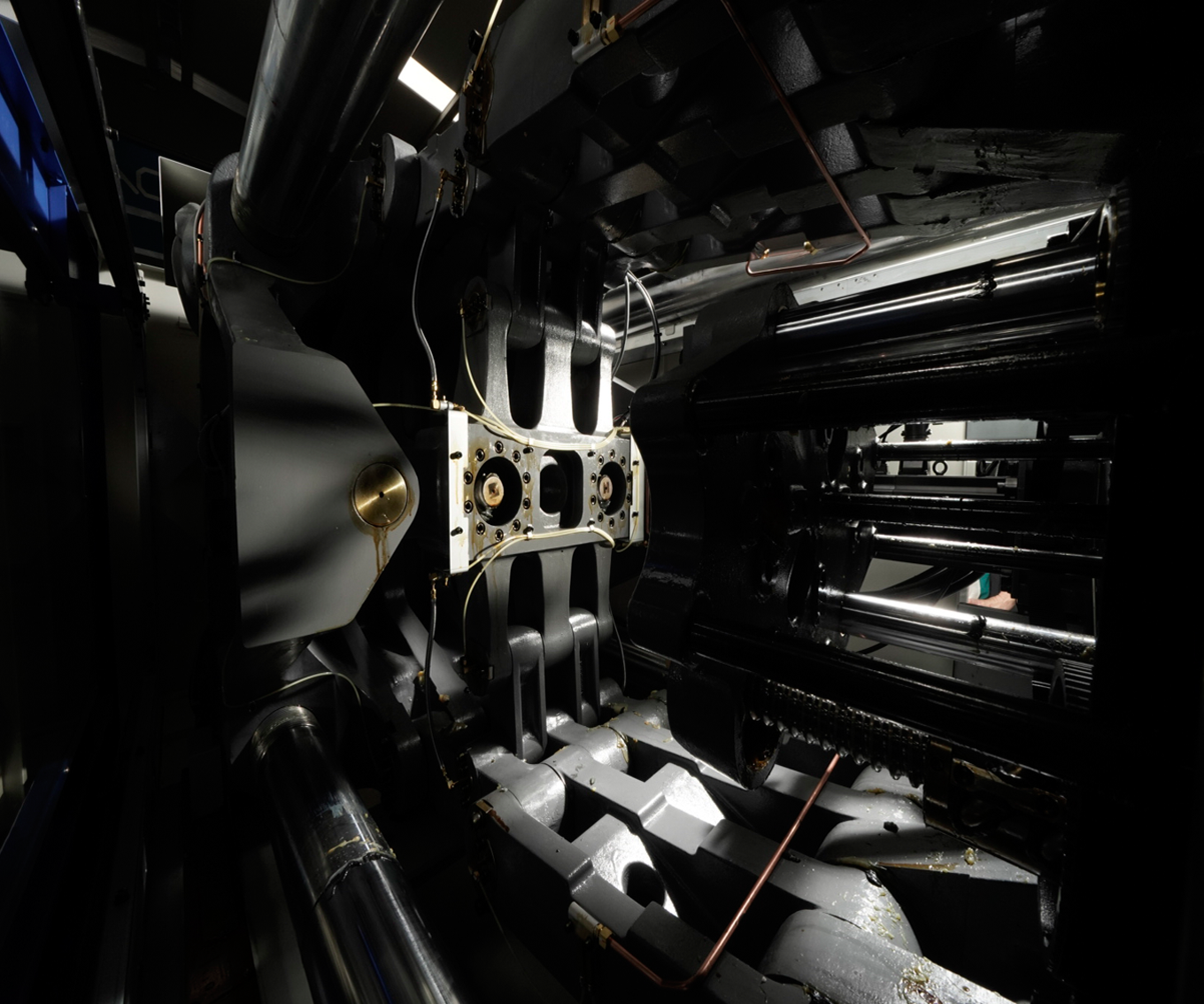

* Clamping System

The optimized kinematics of the proved 5-point toggle represent economical speed and power processes. This allows high sensitivity in the opening and closing processes and protects injection molds from excessive wear and tear. The fast mold closing device is optimized to shorten the cycle time.

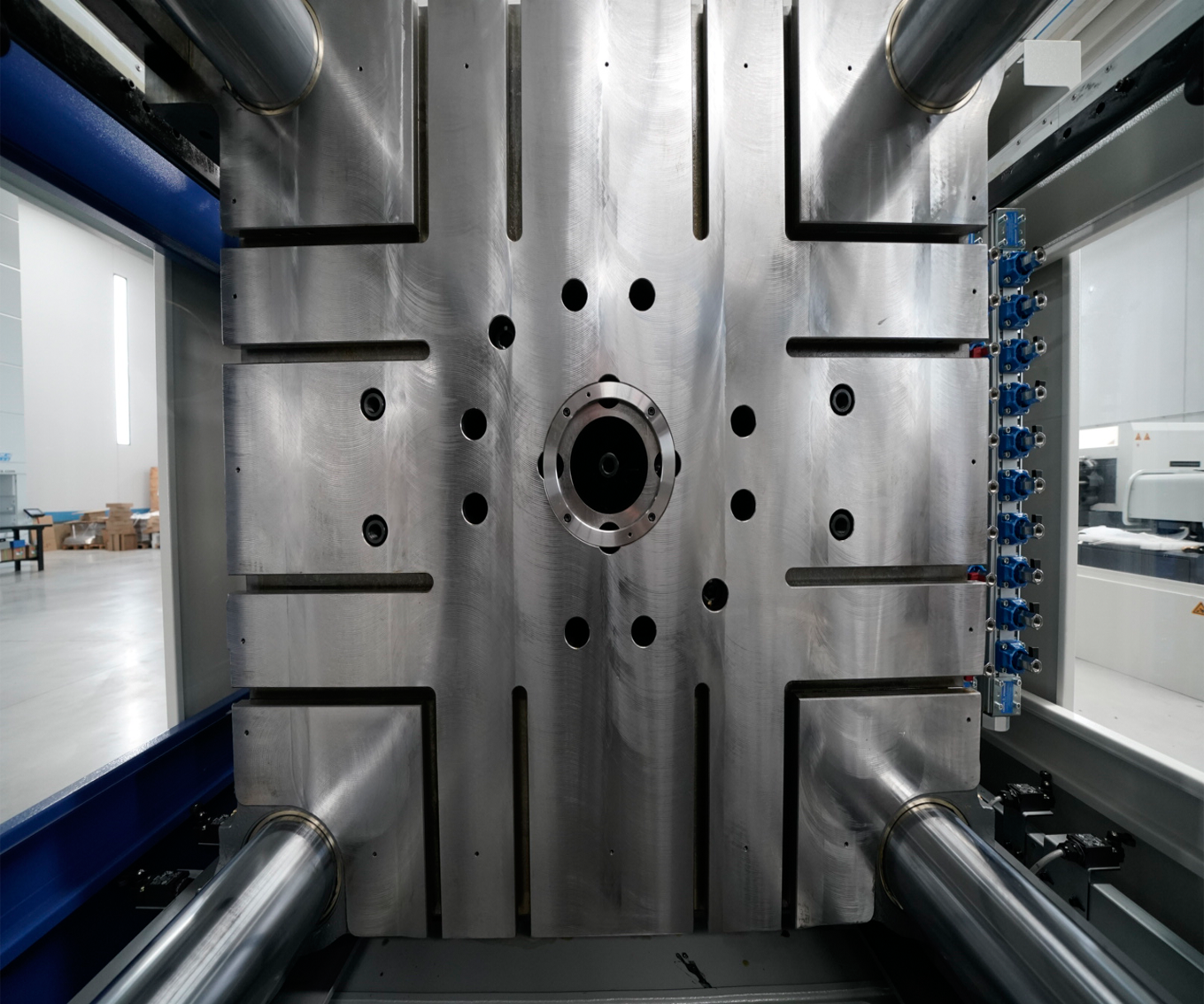

* Automatic Mould Height Adjustment Unit

Automatic Mould-height adjustment by hydraulic motor through the gears system ensures fast and constant settings to different mold heights, achieving platen parallelism and consistent tonnage. The photocell detects function to ensure high precision.

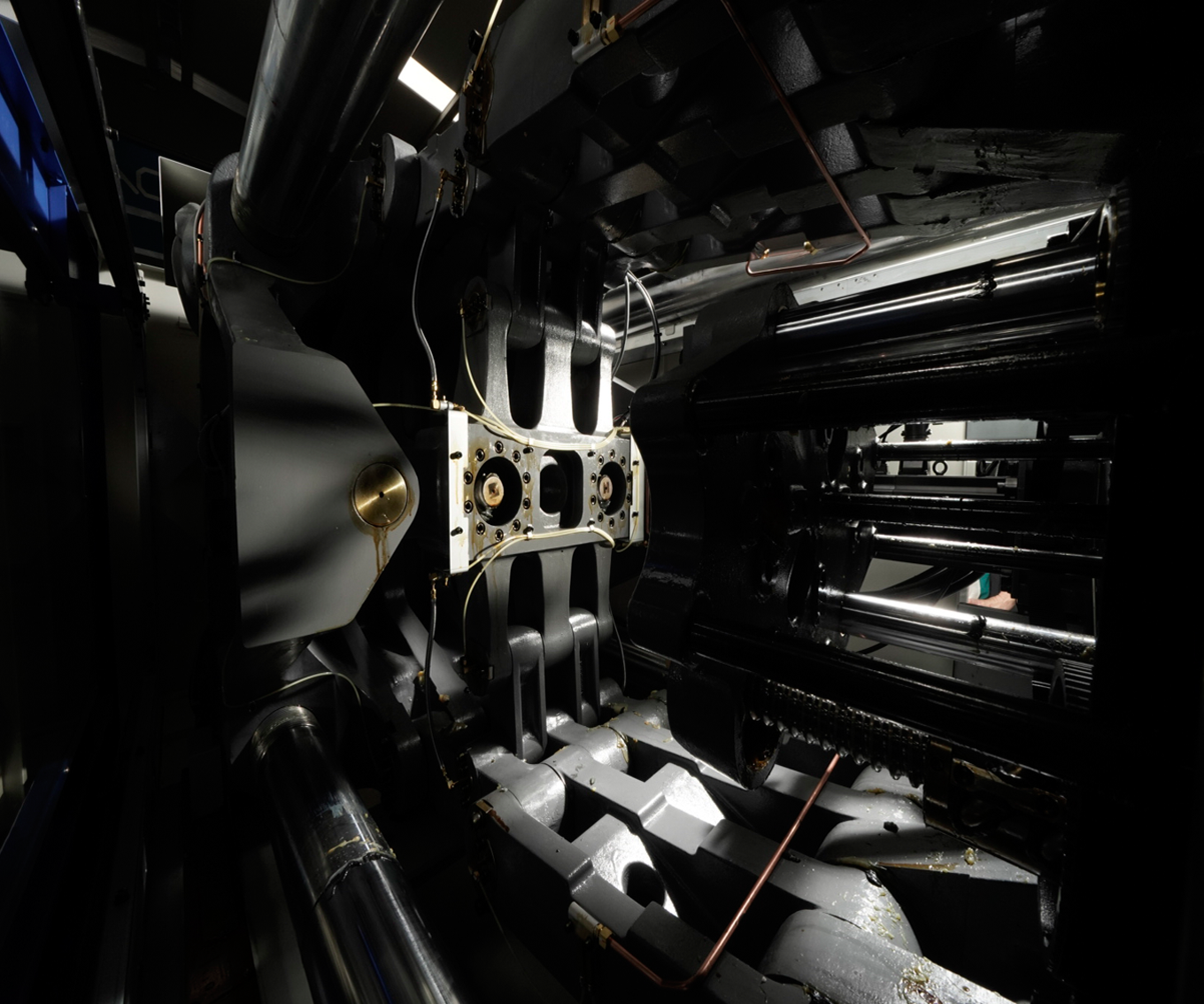

* Hydraulic System

The energy-saving hydraulics are fitted with sound reduced and are made of high-quality components. They allow the transfer of much greater forces and enable very uniform and precise movements of the machine.

SPECIAL FEATURES

❖ Shorter Cycle Time by 20%~30% Through Synchronous Pressure Holding and Charging Process.

❖ Specialized PET Feeding Screw Improves Preform’s Quality.

❖ The Servo Control System Saves 40%~60% of Electricity than Common Model.

| SPECIFICATION | MG-168PET | |

|---|---|---|

| INJECTION UNIT | ||

| Screw Diameter | mm | 50 |

| Screw L/D Ratio | L/D | 20 |

| Short Size (Theoretical) | cm3 | 353 |

| Injection Weight(PET) | G | 458 |

| Injection Rate | g/s | 170 |

| Plasticizing Capacity | g/d | 25 |

| Injection Pressure | Mpa | 136 |

| Screw Speed | rpm | 0~150 |

| CLAMPING UNIT | ||

| Clamp Tonnage | KN | 1680 |

| Toggle Stroke | mm | 430 |

| Space Between Tie Bars | mm | 460×460 |

| Max. Mold Height | mm | 480 |

| Min. Mold Height | mm | 180 |

| Ejector Stroke | mm | 120 |

| Ejector Tonnage | KN | 40 |

| Ejector Number | Piece | 5 |

| OTHERS | ||

| Max. Pump Pressure | Mpa | 16 |

| pump motor Power | kw | 15 |

| Heater Power | kw | 13.00 |

| Machine Dimension(LxWxH) | M | 53×1.4×2.1 |

| Machine Weight | T | 5.2 |

| Hopper Capacity | kg | 25 |

| Oil Tank Capacity | L | 250 |

| SPECIFICATION | MG-398PET | |

|---|---|---|

| INJECTION UNIT | ||

| Screw Diameter | mm | 80 |

| Screw L/D Ratio | L/D | 21 |

| Short Size (Theoretical) | cm3 | 1689 |

| Injection Weight(PET) | G | 2195 |

| Injection Rate | g/s | 446 |

| Plasticizing Capacity | g/d | 70 |

| Injection Pressure | Mpa | 152 |

| Screw Speed | rpm | 0~165 |

| CLAMPING UNIT | ||

| Clamp Tonnage | KN | 3980 |

| Toggle Stroke | mm | 700 |

| Space Between Tie Bars | mm | 720×720 |

| Max. Mold Height | mm | 800 |

| Min. Mold Height | mm | 280 |

| Ejector Stroke | mm | 160 |

| Ejector Tonnage | KN | 110 |

| Ejector Number | Piece | 13 |

| OTHERS | ||

| Max. Pump Pressure | Mpa | 16 |

| pump motor Power | kw | 37 |

| Heater Power | kw | 26.2 |

| Machine Dimension(LxWxH) | M | 7.3×1.9×2.5 |

| Machine Weight | T | 15.7 |

| Hopper Capacity | kg | 50 |

| Oil Tank Capacity | L | 750 |

❖ Food and Beverage

❖ Automotive Parts

❖ Medical & Pharmaceuticals

❖ Household Products

❖ Agriculture

❖ Electronics

- Machine Detail

-

* PLC Controller

The MG series use the latest control technology. This high-performance control system provides excellent communication between the injection molding machine and the operator. The uniform operating concept and logical, clear structure of the functions make machine operation easy and user-oriented.

* PET Injection Unit

Optimized special L/D 25:1 screw, requiring a more extended machine base, is driven by a high output motor for dramatically improving the plasticizing of the PET material to ensure the quality of the PET preform. Increased ejector force consistently ensures the finished parts are ejected automatically.

* Clamping System

The optimized kinematics of the proved 5-point toggle represent economical speed and power processes. This allows high sensitivity in the opening and closing processes and protects injection molds from excessive wear and tear. The fast mold closing device is optimized to shorten the cycle time.

* Automatic Mould Height Adjustment Unit

Automatic Mould-height adjustment by hydraulic motor through the gears system ensures fast and constant settings to different mold heights, achieving platen parallelism and consistent tonnage. The photocell detects function to ensure high precision.

* Hydraulic System

The energy-saving hydraulics are fitted with sound reduced and are made of high-quality components. They allow the transfer of much greater forces and enable very uniform and precise movements of the machine.SPECIAL FEATURES

❖ Shorter Cycle Time by 20%~30% Through Synchronous Pressure Holding and Charging Process.

❖ Specialized PET Feeding Screw Improves Preform’s Quality.

❖ The Servo Control System Saves 40%~60% of Electricity than Common Model. - Parameters

-

SPECIFICATION MG-168PET INJECTION UNIT Screw Diameter mm 50 Screw L/D Ratio L/D 20 Short Size (Theoretical) cm3 353 Injection Weight(PET) G 458 Injection Rate g/s 170 Plasticizing Capacity g/d 25 Injection Pressure Mpa 136 Screw Speed rpm 0~150 CLAMPING UNIT Clamp Tonnage KN 1680 Toggle Stroke mm 430 Space Between Tie Bars mm 460×460 Max. Mold Height mm 480 Min. Mold Height mm 180 Ejector Stroke mm 120 Ejector Tonnage KN 40 Ejector Number Piece 5 OTHERS Max. Pump Pressure Mpa 16 pump motor Power kw 15 Heater Power kw 13.00 Machine Dimension(LxWxH) M 53×1.4×2.1 Machine Weight T 5.2 Hopper Capacity kg 25 Oil Tank Capacity L 250 SPECIFICATION MG-398PET INJECTION UNIT Screw Diameter mm 80 Screw L/D Ratio L/D 21 Short Size (Theoretical) cm3 1689 Injection Weight(PET) G 2195 Injection Rate g/s 446 Plasticizing Capacity g/d 70 Injection Pressure Mpa 152 Screw Speed rpm 0~165 CLAMPING UNIT Clamp Tonnage KN 3980 Toggle Stroke mm 700 Space Between Tie Bars mm 720×720 Max. Mold Height mm 800 Min. Mold Height mm 280 Ejector Stroke mm 160 Ejector Tonnage KN 110 Ejector Number Piece 13 OTHERS Max. Pump Pressure Mpa 16 pump motor Power kw 37 Heater Power kw 26.2 Machine Dimension(LxWxH) M 7.3×1.9×2.5 Machine Weight T 15.7 Hopper Capacity kg 50 Oil Tank Capacity L 750 - Applications

-

❖ Food and Beverage

❖ Automotive Parts

❖ Medical & Pharmaceuticals

❖ Household Products

❖ Agriculture

❖ Electronics - Video

-