-

-

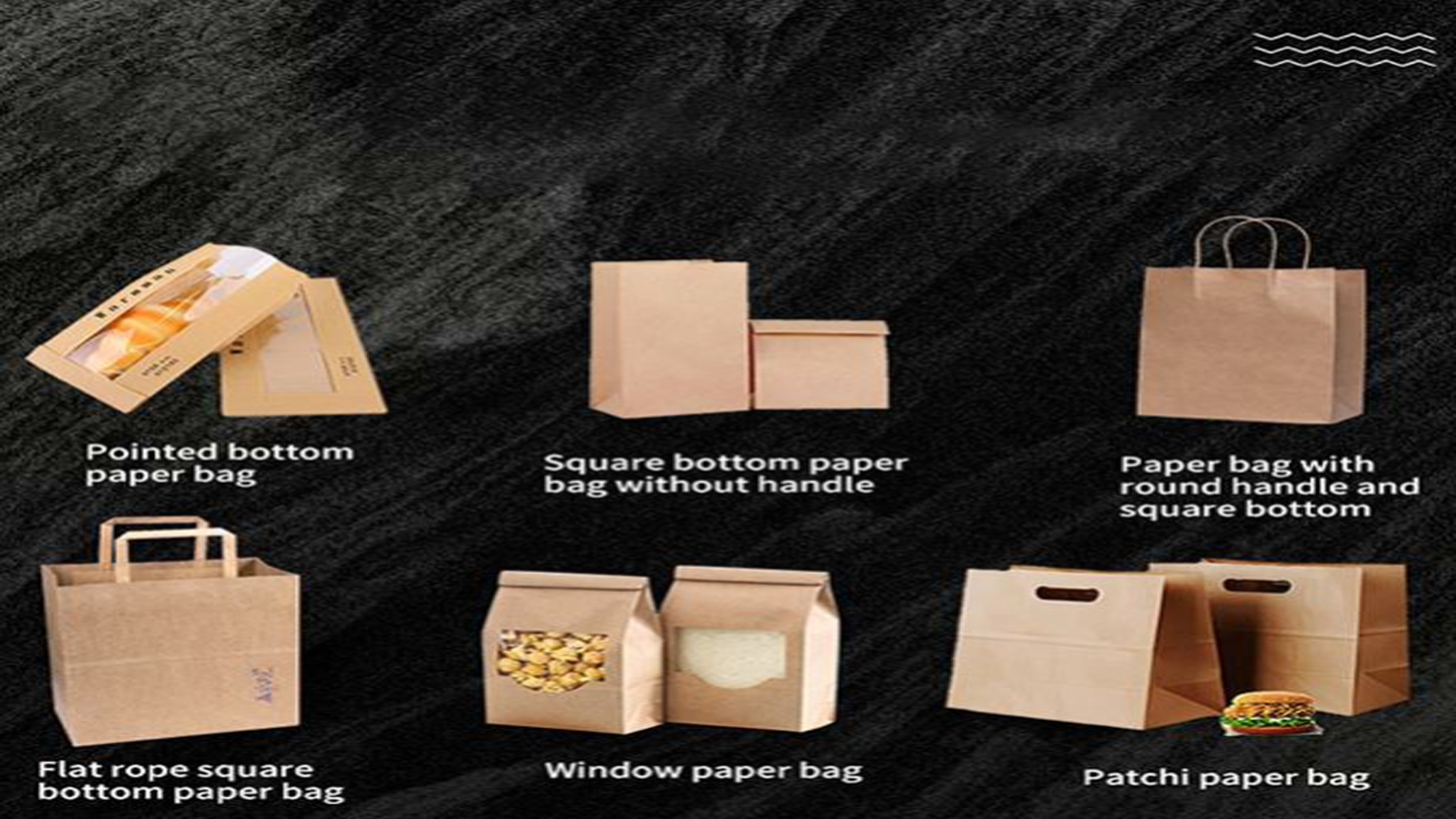

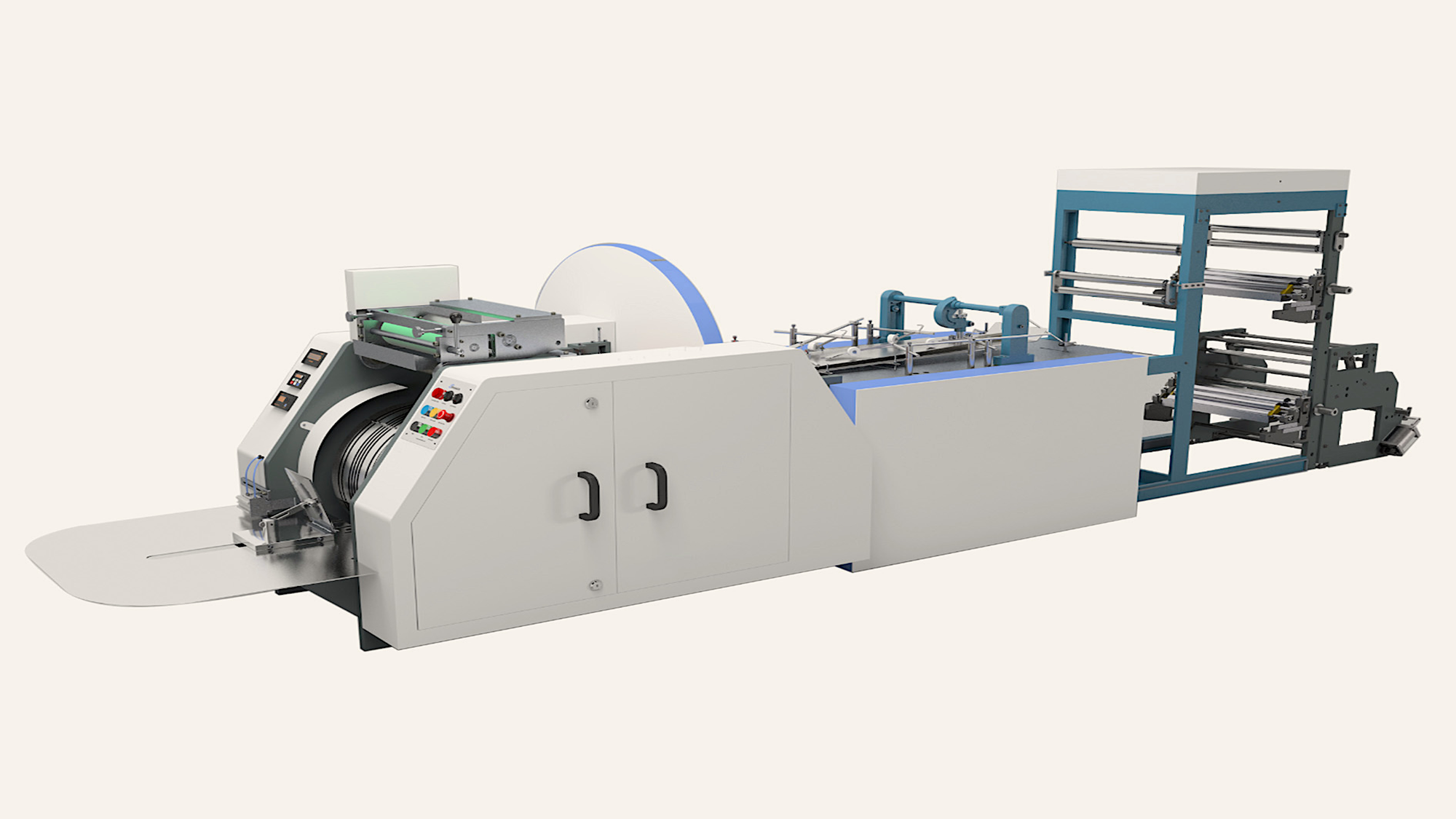

- Fully Automatic and High Speed

- Automatic Braking System

- Gusset Adjustment

- Pneumatic Reel Lifting System

- Counters

- Special Design of Size Plate

-

- ❖ Machine is fully automatic and runs at high speed of 400 bags per minute with 4 rotating blades. This translates into high production with minimum manpower.

- ❖ Automatic tension control system is provided with pneumatic disc brake at unwind unit. This helps in maintaining flow of paper to the machine and tension is automatically Adjusted with carrying reel diameter.

- ❖ Machines is equipped with pneumatic reel lifting to ease the operation and better roll handling.

- ❖ Both side gusset can be adjusted in tandem from one knob. This helps the operator to adjust gusset depth on the run with precision.

- ❖ Total production counter, settable batch counter, and drive counters are all available in one place on the operating side.

- ❖ Size plate for tube formation is of unique design and radius, which enables high speed production, less breakdowns and quick size changeovers.

Fully Automatic and High Speed

Machine is fully automatic and runs at high speed of 400 bags per minute with 4 rotating blades. This translates into high production with minimum manpower.

Automatic Braking System

Automatic tension control system is provided with pneumatic disc brake at unwind unit. This helps in maintaining flow of paper to the machine and tension is automatically Adjusted with carying reel diameter.

Gusset Adjustment

Both side gusset can be adjusted in tandem from one knob. This helps ther operator to adjust gusset debpth on the run with precision.

Pneumatic Reel Lifting System

Machines is equipped with pneumatic reel lifting to ease the operation and better roll handling.

Counters

Total production counter, settable batch counter, drive counter are all available at one place at operating side.

Special Design of Size Plate

Size plate for tube formation is of unique design and radius, which enables high speed production, less breakdowns and quick size changeovers.

PLC Controller

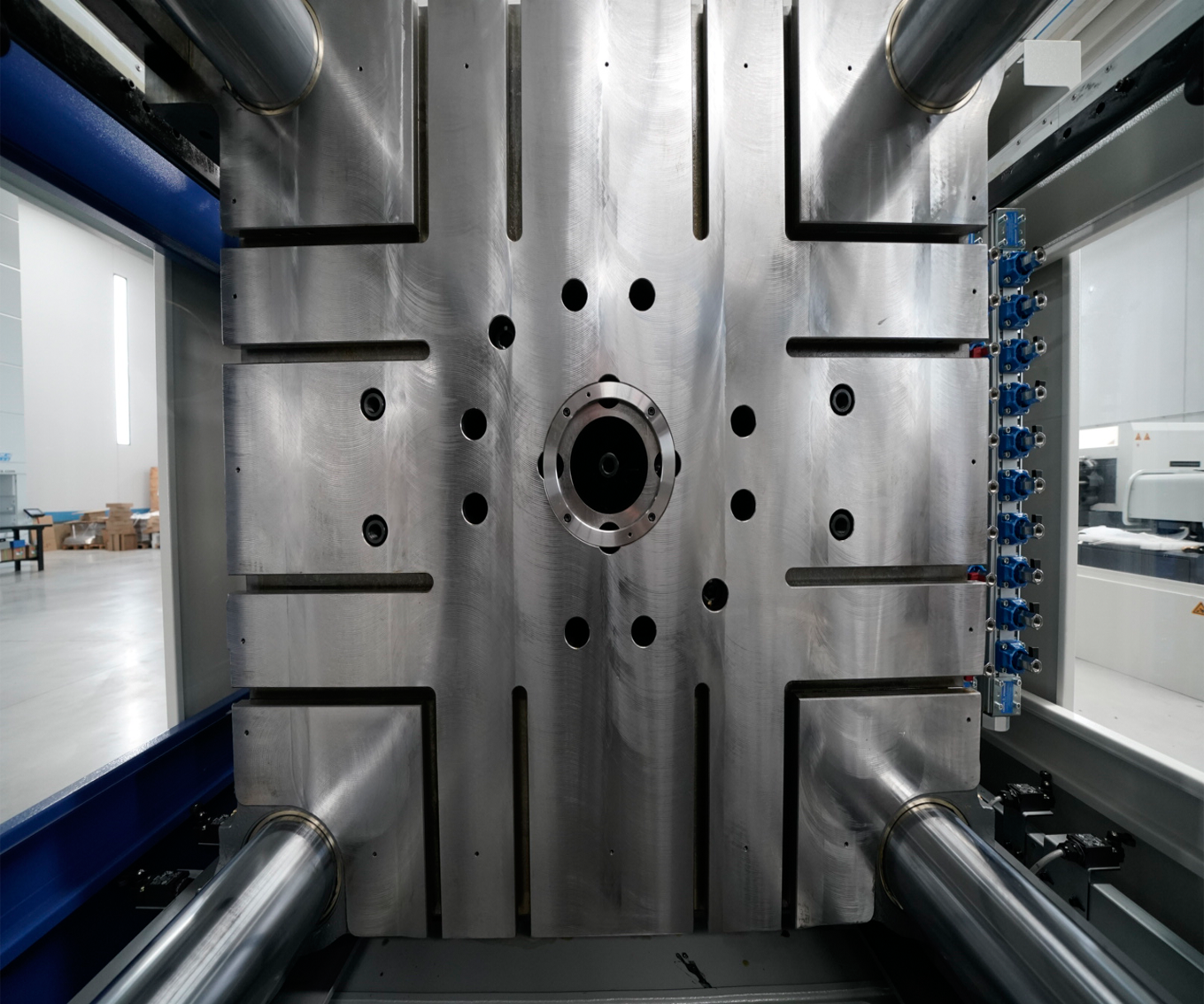

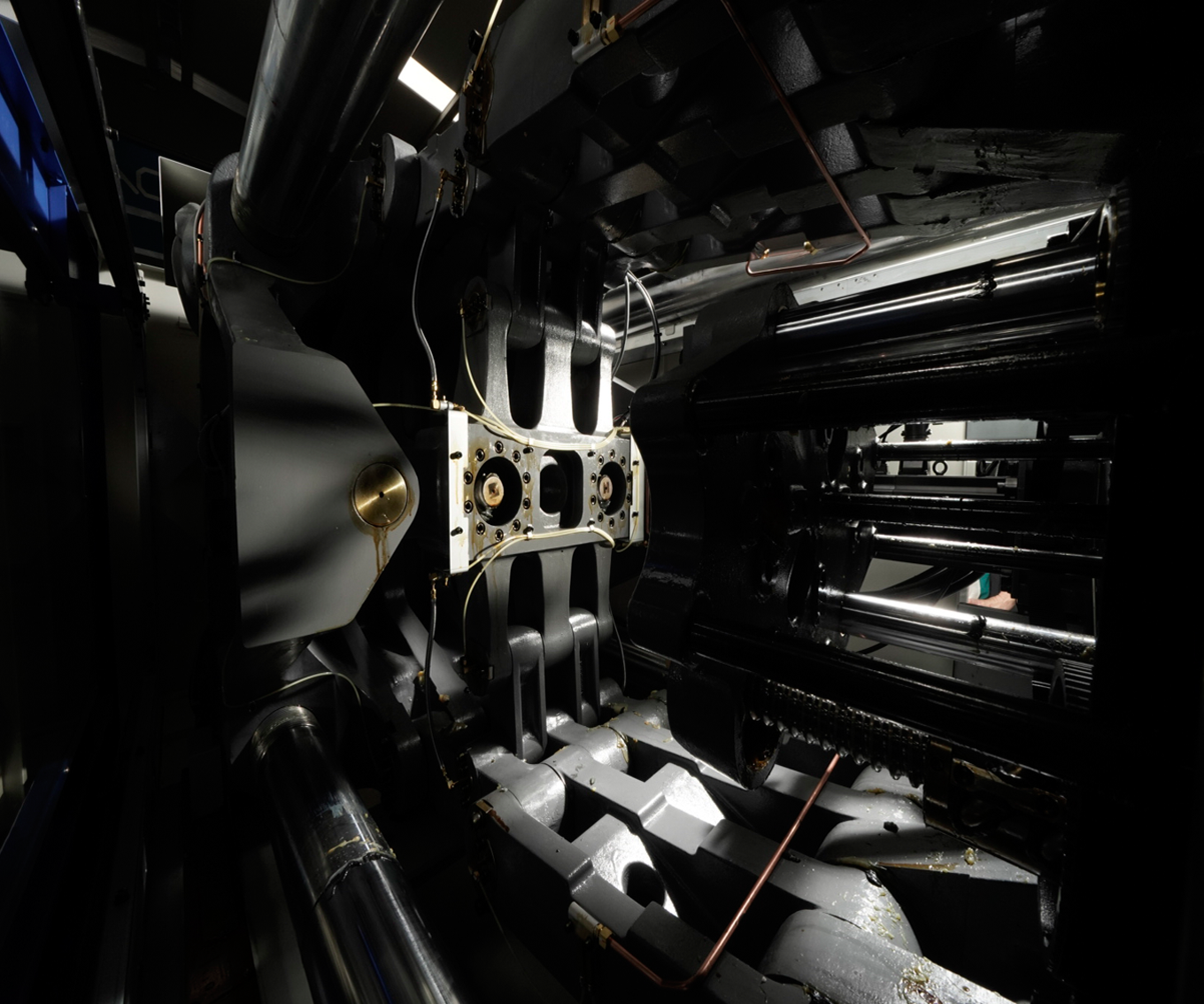

PET Injection Unit

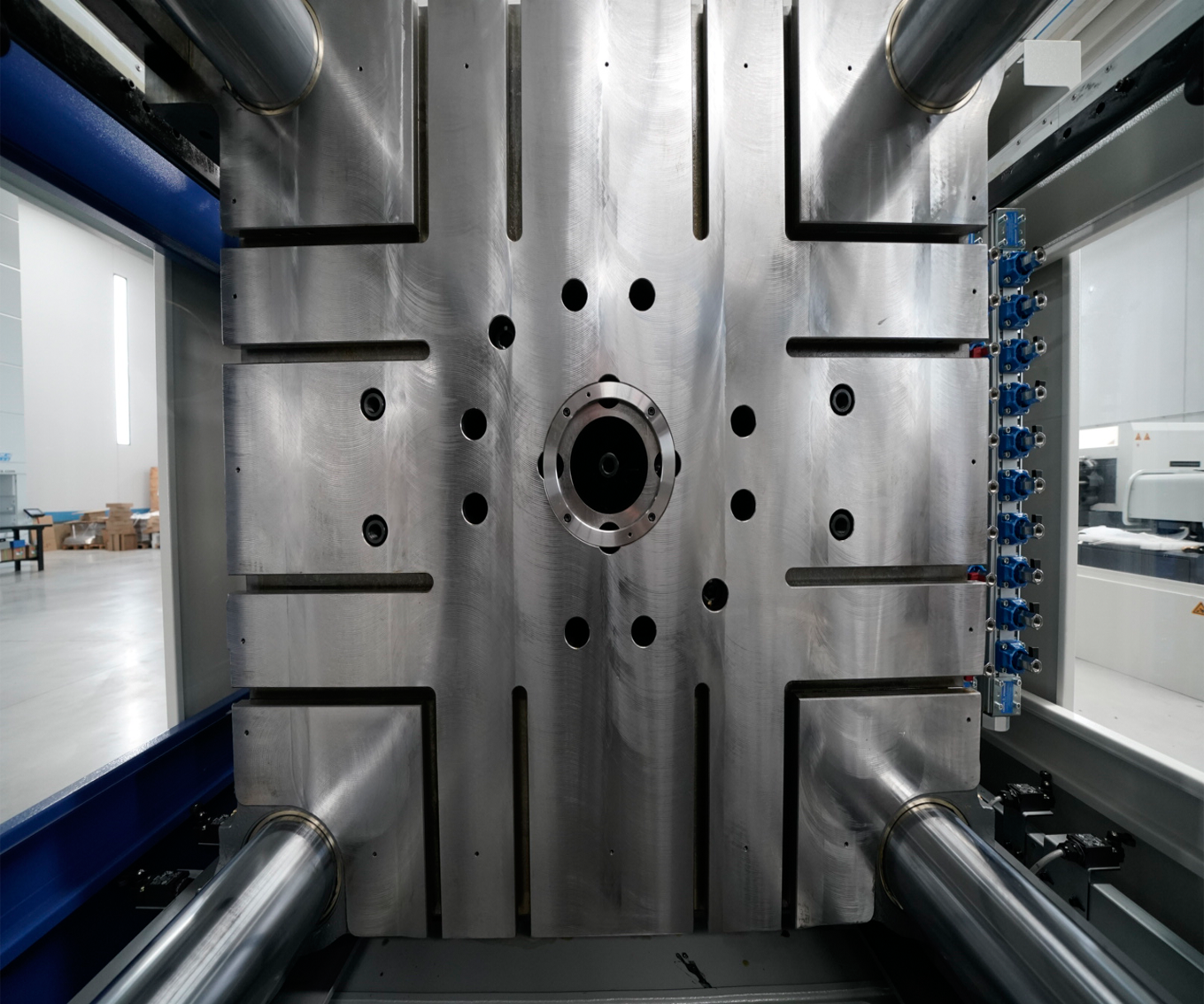

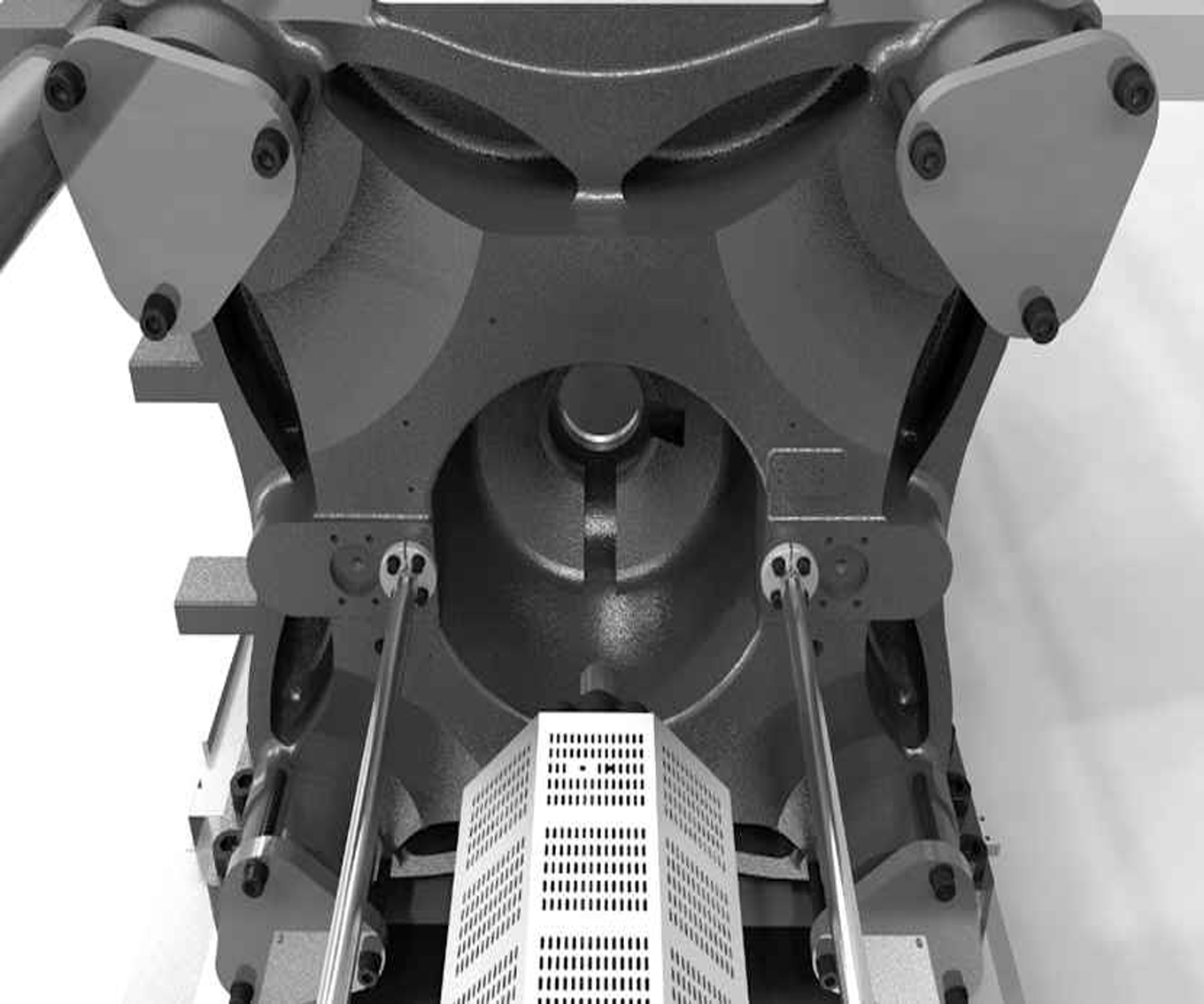

Clamping System

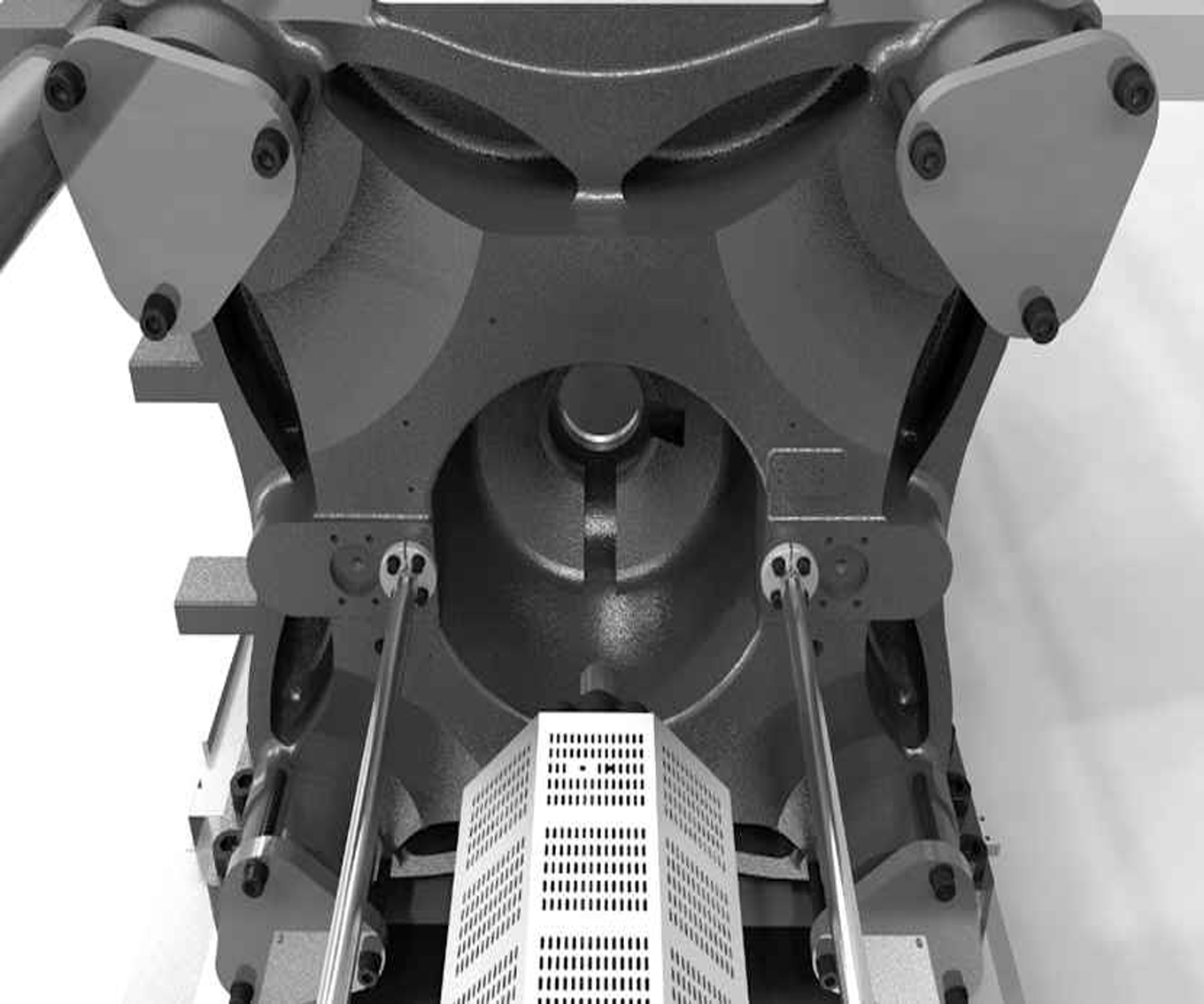

Automatic Mould Height Adjustment Unit

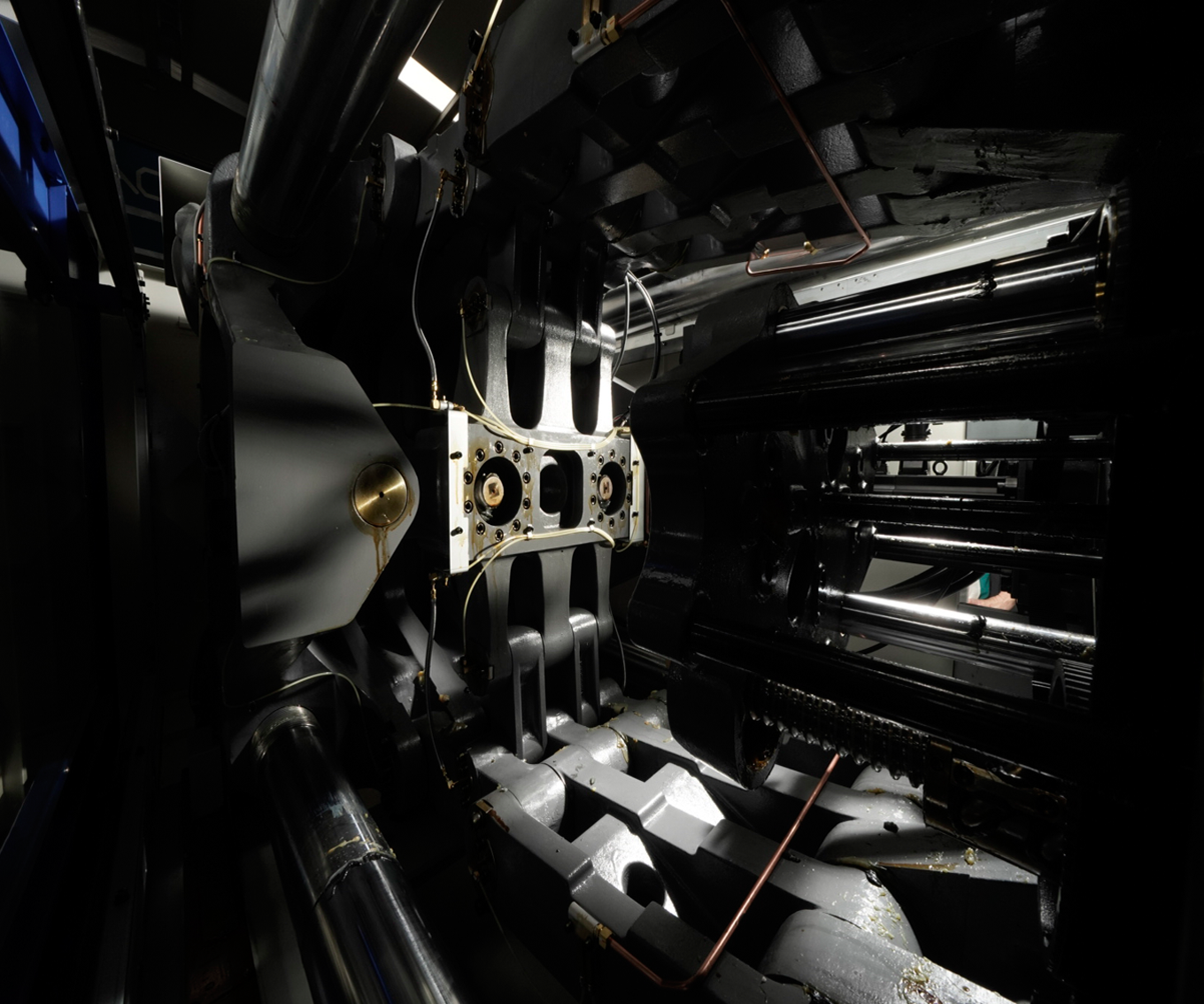

Hydraulic System

| SPECIFICATION | MG-168PET | |

|---|---|---|

| INJECTION UNIT | ||

| Screw Diameter | mm | 50 |

| Screw L/D Ratio | L/D | 20 |

| Short Size (Theoretical) | cm3 | 353 |

| Injection Weight(PET) | G | 458 |

| Injection Rate | g/s | 170 |

| Plasticizing Capacity | g/d | 25 |

| Injection Pressure | Mpa | 136 |

| Screw Speed | rpm | 0~150 |

| CLAMPING UNIT | ||

| Clamp Tonnage | KN | 1680 |

| Toggle Stroke | mm | 430 |

| Space Between Tie Bars | mm | 460×460 |

| Max. Mold Height | mm | 480 |

| Min. Mold Height | mm | 180 |

| Ejector Stroke | mm | 120 |

| Ejector Tonnage | KN | 40 |

| Ejector Number | Piece | 5 |

| OTHERS | ||

| Max. Pump Pressure | Mpa | 16 |

| pump motor Power | kw | 15 |

| Heater Power | kw | 13.00 |

| Machine Dimension(LxWxH) | M | 53×1.4×2.1 |

| Machine Weight | T | 5.2 |

| Hopper Capacity | kg | 25 |

| Oil Tank Capacity | L | 250 |

| SPECIFICATION | MG-398PET | |

|---|---|---|

| INJECTION UNIT | ||

| Screw Diameter | mm | 80 |

| Screw L/D Ratio | L/D | 21 |

| Short Size (Theoretical) | cm3 | 1689 |

| Injection Weight(PET) | G | 2195 |

| Injection Rate | g/s | 446 |

| Plasticizing Capacity | g/d | 70 |

| Injection Pressure | Mpa | 152 |

| Screw Speed | rpm | 0~165 |

| CLAMPING UNIT | ||

| Clamp Tonnage | KN | 3980 |

| Toggle Stroke | mm | 700 |

| Space Between Tie Bars | mm | 720×720 |

| Max. Mold Height | mm | 800 |

| Min. Mold Height | mm | 280 |

| Ejector Stroke | mm | 160 |

| Ejector Tonnage | KN | 110 |

| Ejector Number | Piece | 13 |

| OTHERS | ||

| Max. Pump Pressure | Mpa | 16 |

| pump motor Power | kw | 37 |

| Heater Power | kw | 26.2 |

| Machine Dimension(LxWxH) | M | 7.3×1.9×2.5 |

| Machine Weight | T | 15.7 |

| Hopper Capacity | kg | 50 |

| Oil Tank Capacity | L | 750 |

❖ Food and Beverage

❖ Automotive Parts

❖ Medical & Pharmaceuticals

❖ Household Products

❖ Agriculture

❖ Electronics

- Machine Detail

-

PLC Controller

PET Injection Unit

Clamping System

Automatic Mould Height Adjustment Unit

Hydraulic System

- Parameters

-

SPECIFICATION MG-168PET INJECTION UNIT Screw Diameter mm 50 Screw L/D Ratio L/D 20 Short Size (Theoretical) cm3 353 Injection Weight(PET) G 458 Injection Rate g/s 170 Plasticizing Capacity g/d 25 Injection Pressure Mpa 136 Screw Speed rpm 0~150 CLAMPING UNIT Clamp Tonnage KN 1680 Toggle Stroke mm 430 Space Between Tie Bars mm 460×460 Max. Mold Height mm 480 Min. Mold Height mm 180 Ejector Stroke mm 120 Ejector Tonnage KN 40 Ejector Number Piece 5 OTHERS Max. Pump Pressure Mpa 16 pump motor Power kw 15 Heater Power kw 13.00 Machine Dimension(LxWxH) M 53×1.4×2.1 Machine Weight T 5.2 Hopper Capacity kg 25 Oil Tank Capacity L 250 SPECIFICATION MG-398PET INJECTION UNIT Screw Diameter mm 80 Screw L/D Ratio L/D 21 Short Size (Theoretical) cm3 1689 Injection Weight(PET) G 2195 Injection Rate g/s 446 Plasticizing Capacity g/d 70 Injection Pressure Mpa 152 Screw Speed rpm 0~165 CLAMPING UNIT Clamp Tonnage KN 3980 Toggle Stroke mm 700 Space Between Tie Bars mm 720×720 Max. Mold Height mm 800 Min. Mold Height mm 280 Ejector Stroke mm 160 Ejector Tonnage KN 110 Ejector Number Piece 13 OTHERS Max. Pump Pressure Mpa 16 pump motor Power kw 37 Heater Power kw 26.2 Machine Dimension(LxWxH) M 7.3×1.9×2.5 Machine Weight T 15.7 Hopper Capacity kg 50 Oil Tank Capacity L 750 - Applications

-

❖ Food and Beverage

❖ Automotive Parts

❖ Medical & Pharmaceuticals

❖ Household Products

❖ Agriculture

❖ Electronics - Video

-