→

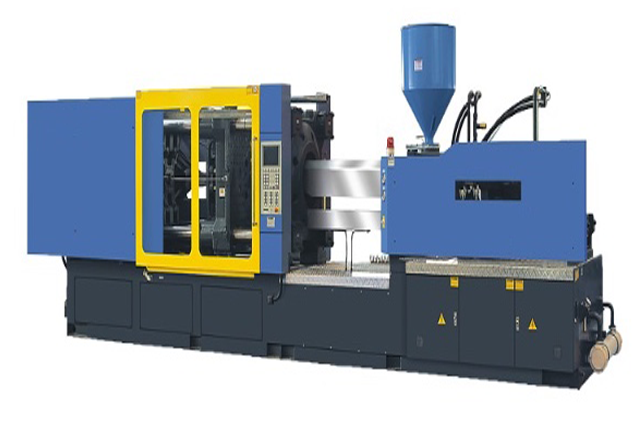

PET SERIES

PET Series is highly energy-serving. With our Standard Injection Molding Machine’s new driving system, the motor will stop at the cooling stage to save energy and can provide higher injection speed and accuracy. It has a wide range of clamping forces (1680-2680)KN, and the driving system is hydraulic with a servo motor type. This series is applied widely in food and beverage packaging, necessity products, home appliances, electrical components, and automotive parts.

STANDARD TYPE

→

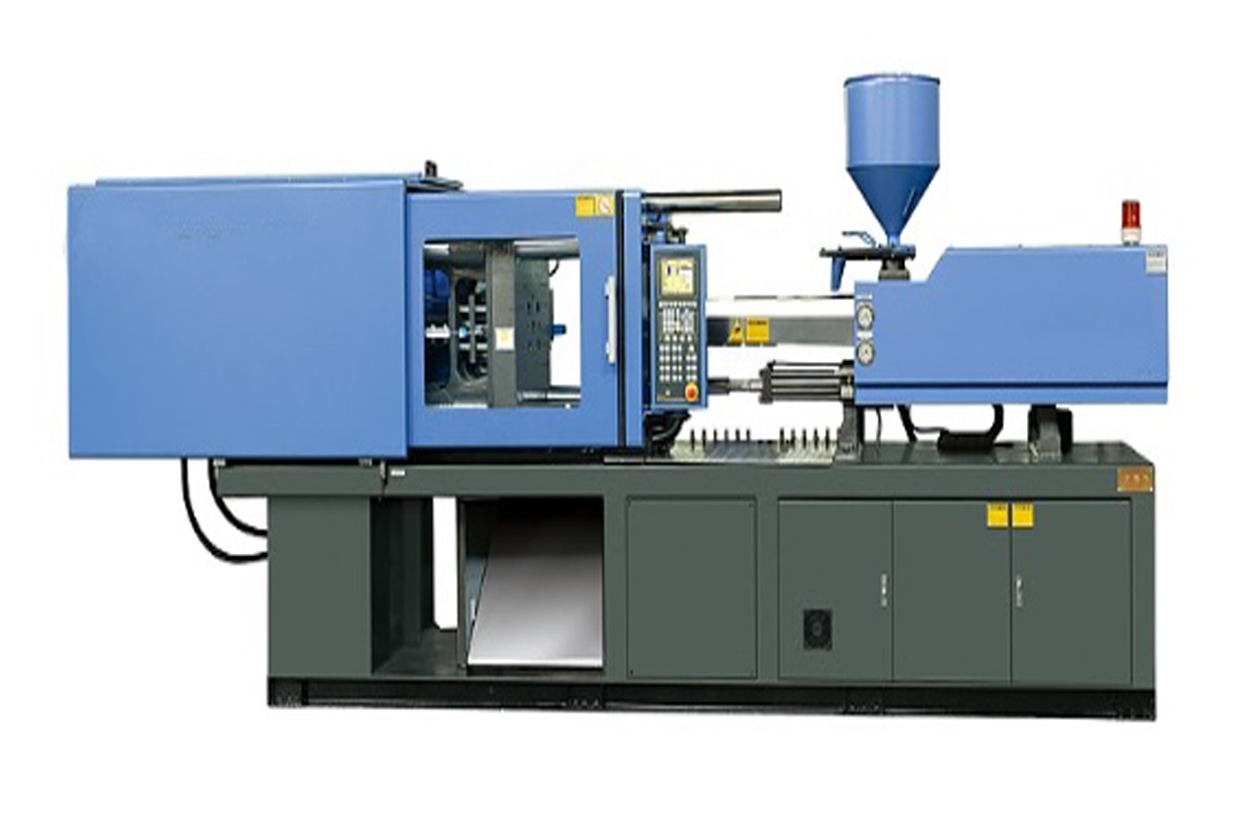

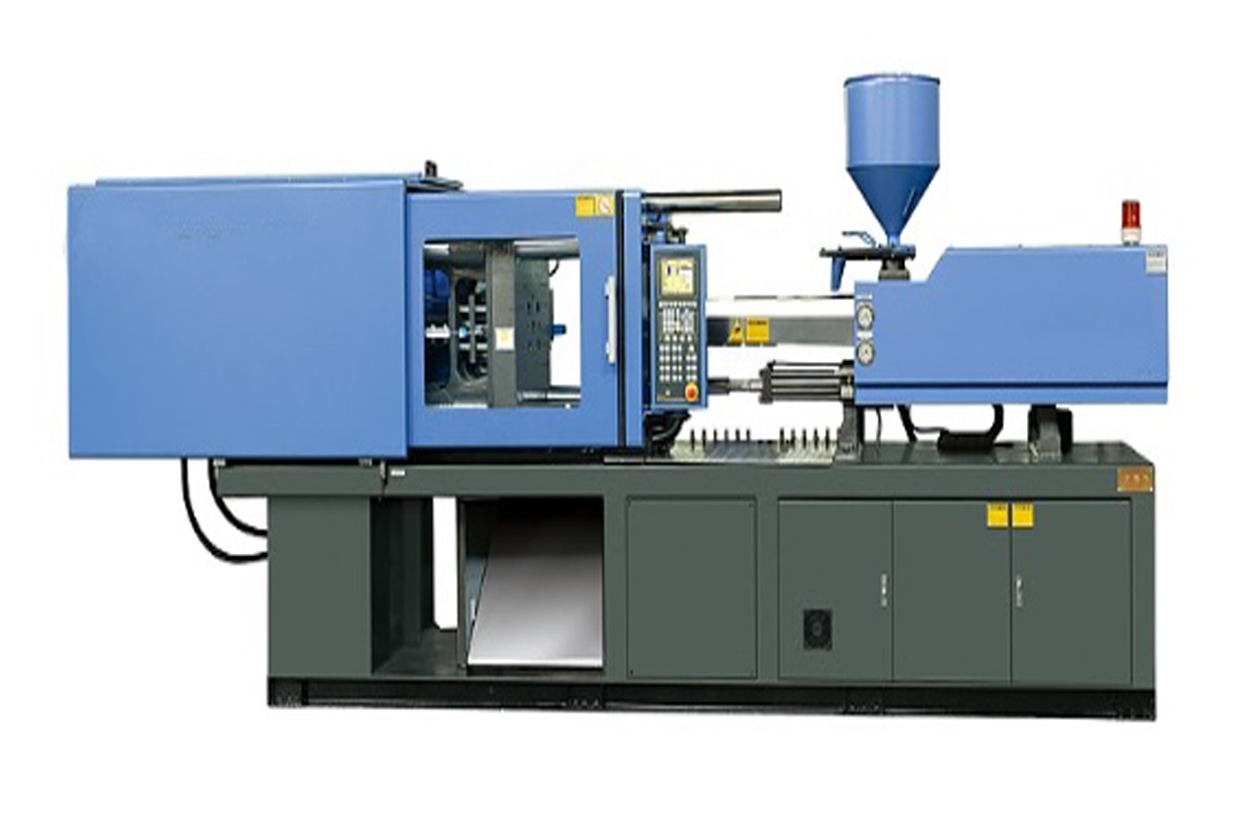

MG SERIES

MAD New Series Hydraulic Injection Molding Machine with faster injection and plasticizing speed is more stable, cost-effective, and highly efficient. It has a wide range of clamping forces (960-1680)KN, and the driving system is hydraulic with a servo motor type. This series is applied widely in food and beverage packaging, necessity products, home appliances, electrical components, and automotive parts.

HIGH PRECISION

→

PET Series is highly energy-serving. With our Standard Injection Molding Machine’s new driving system, the motor will stop at the cooling stage to save energy and can provide higher injection speed and accuracy. It has a wide range of clamping forces (1680-2680)KN, and the driving system is hydraulic with a servo motor type. This series is applied widely in food and beverage packaging, necessity products, home appliances, electrical components, and automotive parts.

Energy-saving Injection Molding Machine

→

MAD New Series Hydraulic Injection Molding Machine with faster injection and plasticizing speed is more stable, cost-effective, and highly efficient. It has a wide range of clamping forces (960-1680)KN, and the driving system is hydraulic with a servo motor type. This series is applied widely in food and beverage packaging, necessity products, home appliances, electrical components, and automotive parts.

→

MAD Medical Instrument Injection Molding Machines are specialized for manufacturing medical instruments like syringes, blood collection tubes, infusion parts, and more. The machine is very hygienic to prevent contamination. It has a clamping force (258)KN, and the driving system is hydraulic with a servo motor type. This series is applied widely in medical instrument products.

→

Plastic crates are low-margin products made with recycled material. It requires machines with high production efficiency. The Plastic Crates Injection Molding Machine works perfectly well with the crate molds, ensuring higher production capability and stable product quality. It has a wide range of clamping forces (400-500)KN, and the driving system is hydraulic with a servo motor type. This series is applied widely in plastic crates for food and non-food products.

→

MAD has been involved with the PET Preform molding system since the late 80th. MAD provides different options for our PET machine, such as the additional pressure holding system, the 25:1 PET screw with an extended frame base, double pumps system for better plasticizing effect, two-stage injection systems for faster cycle time, and a post-cooling system for the preforms. PRODUCT DETIALS

PET Preform Injection Molding Machine

→

MAD new series PVC fitting injection molding machines are specialized for different sizes of PVC fitting. They save up to 30%~50% of their energy using servo motors. It can be customized based on the customer’s requirements. It has a wide range of clamping forces (90-680)KN, and the driving system is hydraulic with a servo motor type. This series is applied widely in PVC fitting

PVC Fitting Injection Molding Machine

MAD Medical Instrument Injection Molding Machines are specialized for manufacturing medical instruments like syringes, blood collection tubes, infusion parts, and more. The machine is very hygienic to prevent contamination. It has a clamping force (258)KN, and the driving system is hydraulic with a servo motor type. This series is applied widely in medical instrument products.

Plastic crates are low-margin products made with recycled material. It requires machines with high production efficiency. The Plastic Crates Injection Molding Machine works perfectly well with the crate molds, ensuring higher production capability and stable product quality. It has a wide range of clamping forces (400-500)KN, and the driving system is hydraulic with a servo motor type. This series is applied widely in plastic crates for food and non-food products.

MAD has been involved with the PET Preform molding system since the late 80th. MAD provides different options for our PET machine, such as the additional pressure holding system, the 25:1 PET screw with an extended frame base, double pumps system for better plasticizing effect, two-stage injection systems for faster cycle time, and a post-cooling system for the preforms.

PRODUCT DETIALS

MAD new series PVC fitting injection molding machines are specialized for different sizes of PVC fitting. They save up to 30%~50% of their energy using servo motors. It can be customized based on the customer’s requirements. It has a wide range of clamping forces (90-680)KN, and the driving system is hydraulic with a servo motor type. This series is applied widely in PVC fitting.