-

-

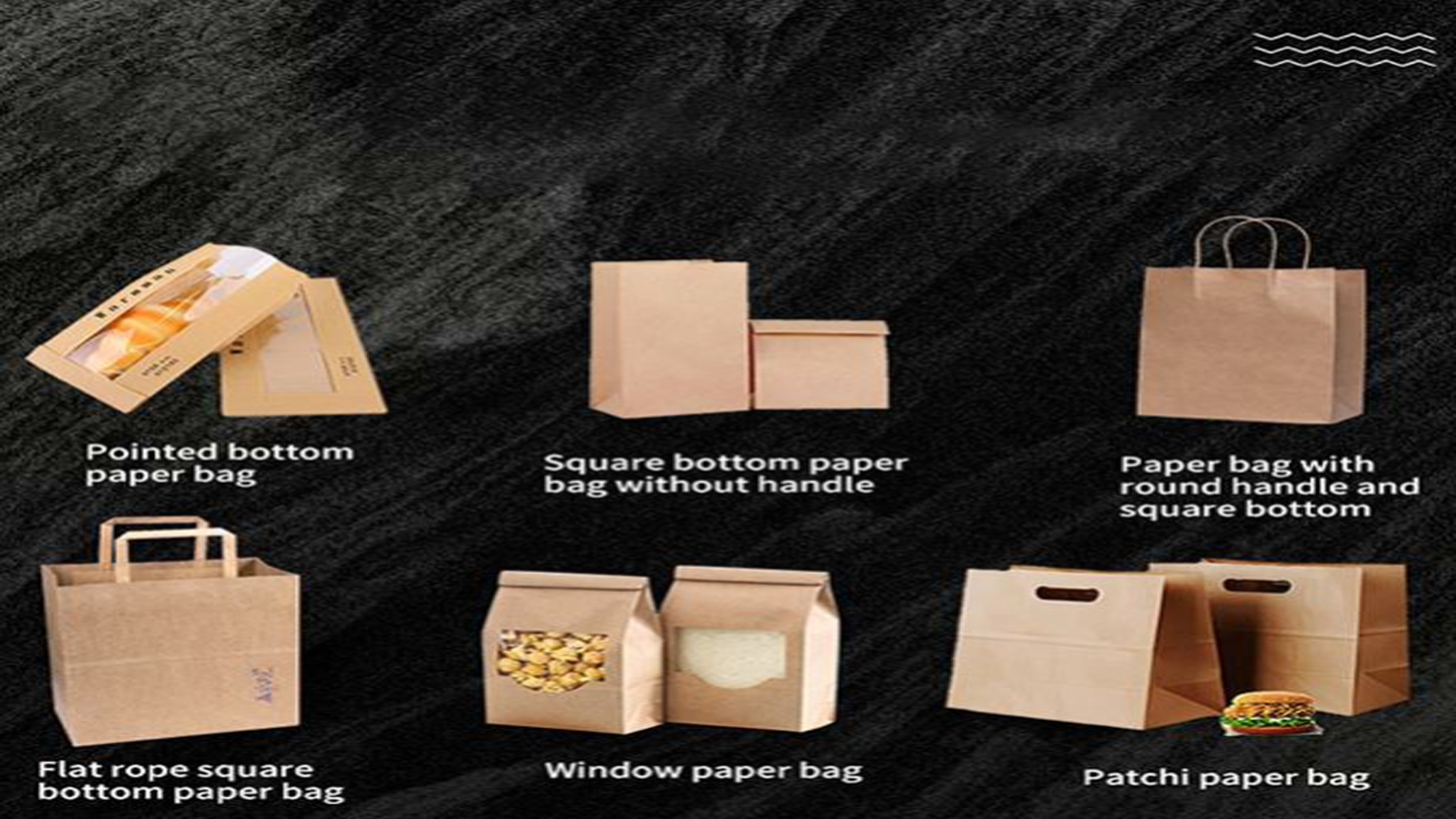

- Compact Design

- Fully automatic

- Fully automatic glue supply system

- Automatic Braking System

- Gusset adjustment

-

- ❖ Easy to use and operator friendly machine, helps in giving high production and maintenance free.

- ❖ Fully automatic with plc control gives full control over the machine.

- ❖ Small footprint enables easy stallation and less space requirement.

- ❖ Automatic lubrication system, increases machine life considerably.

- ❖ Pneumatic reel lifting helps in quick changeover and less labor.

- ❖ Auto tensions control system keeps bag quality and finishing as per the international standards.

- ❖ Automatic counting system helps in easy collection of finished paper bags and sampler production planning.

Compact Design

The paper bag-making machine’s design makes sure that the paper runs effortlessly. This helps in the production of good-quality paper bags with great finishes.

Fully automatic

Our paper bag making machine in India is fully automatic and it runs at a good speed. It can produce 400 bags per minute with 4 rotating blades.

Fully automatic glue supply system

The automatic glue supply system is there to ensure there is enough glue in the machines. If the glue tank is low, it will get replenished to prevent glue solidification after the machine has stopped.

Automatic Braking System

Automatic tension control system is added with a pneumatic disc brake. This will help in maintaining the flow of paper to the machine and also will help in adjusting the tension automatically.

Gusset adjustment

Both the gusset can be easily adjusted in tandem with the help of one knob. This helps the operator to easily adjust gusset depth on the run with precision.

PLC Controller

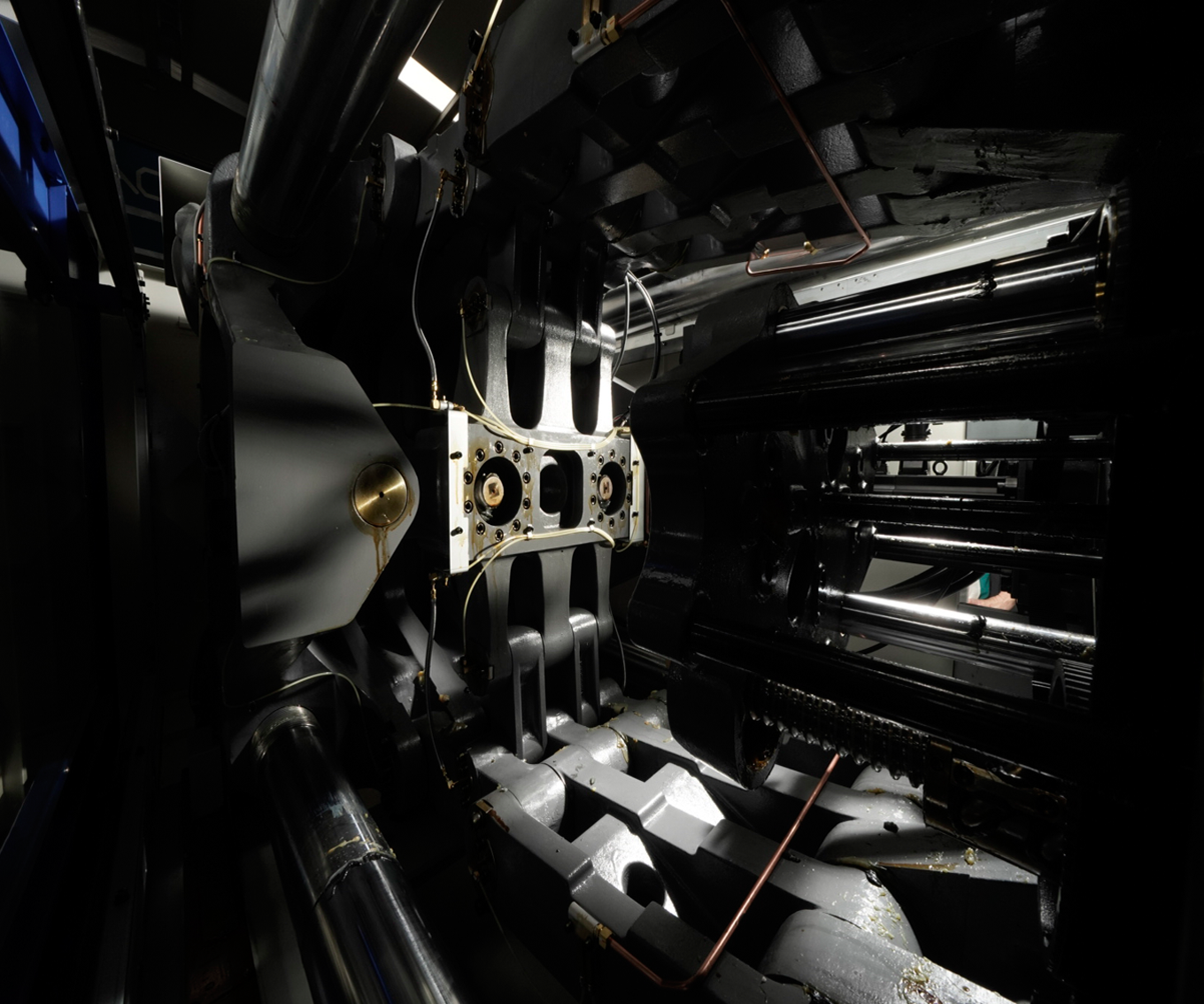

PET Injection Unit

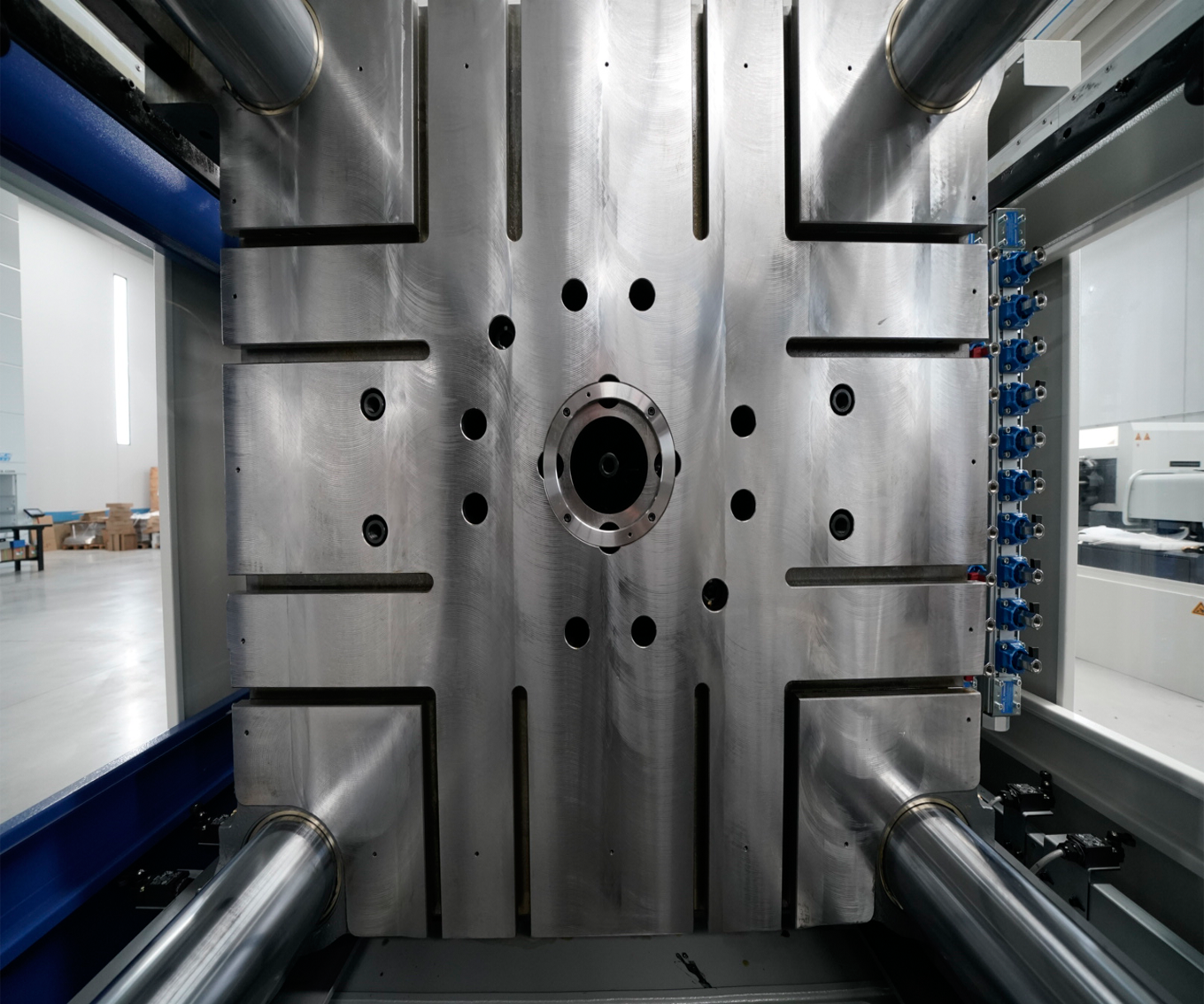

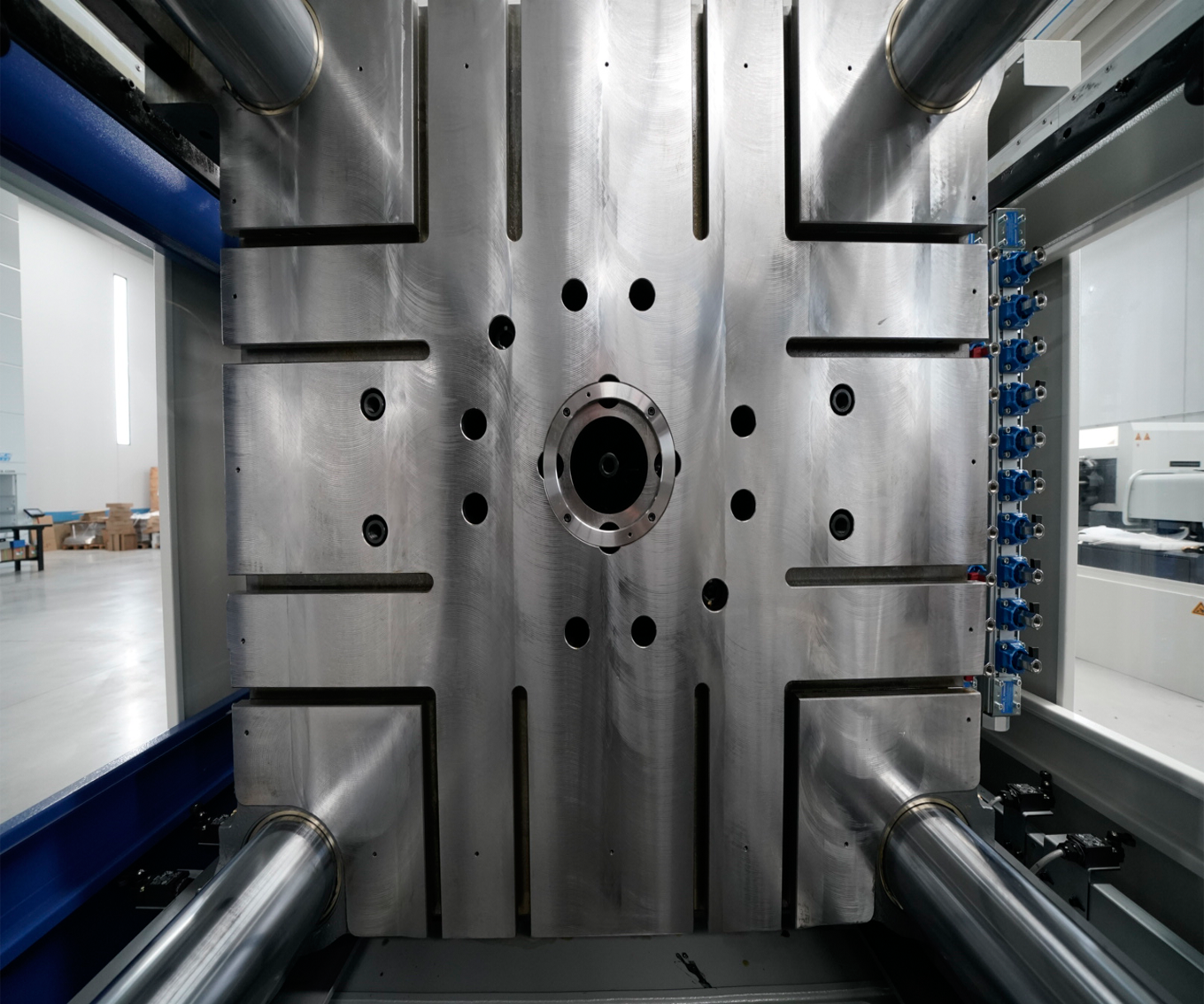

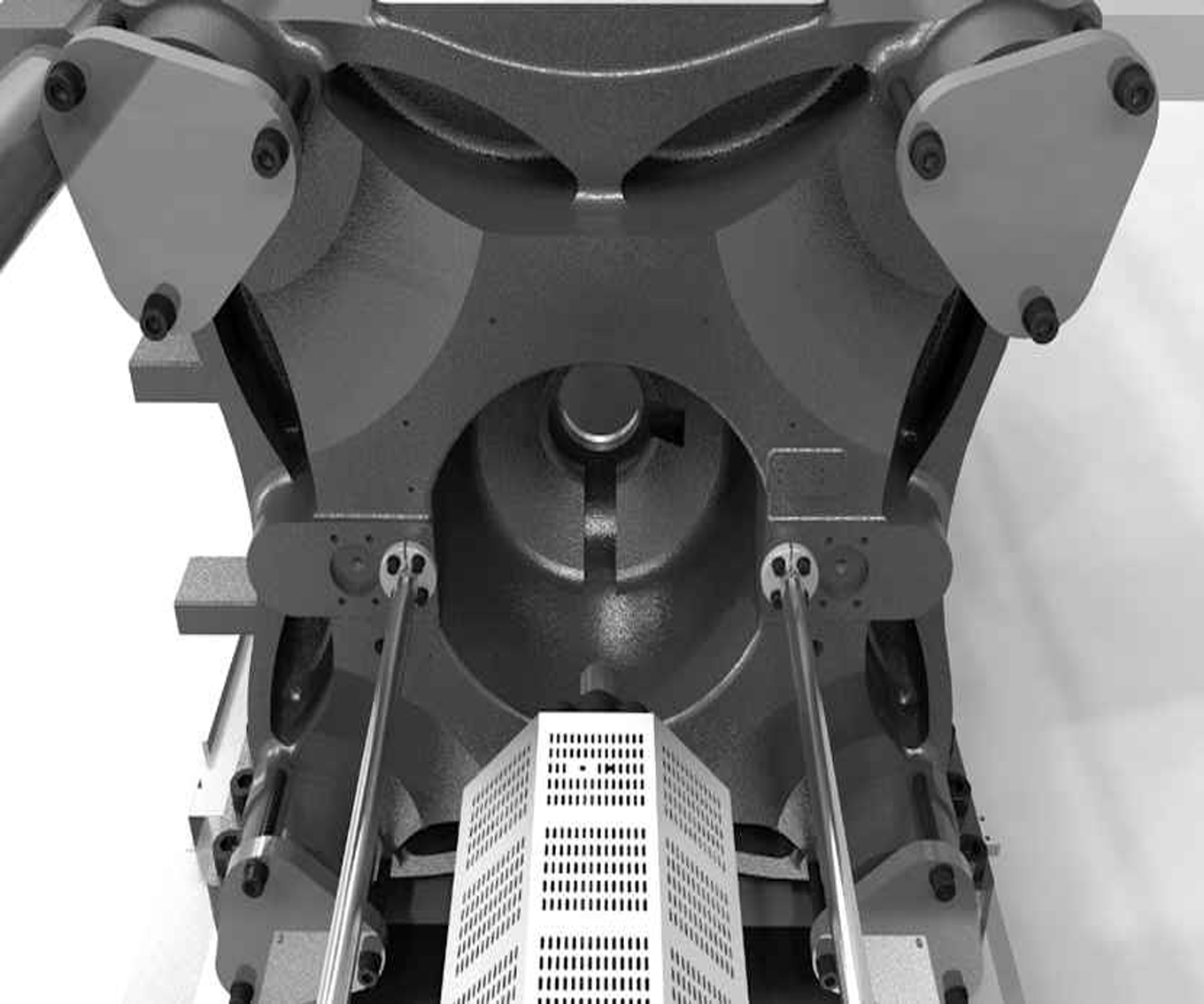

Clamping System

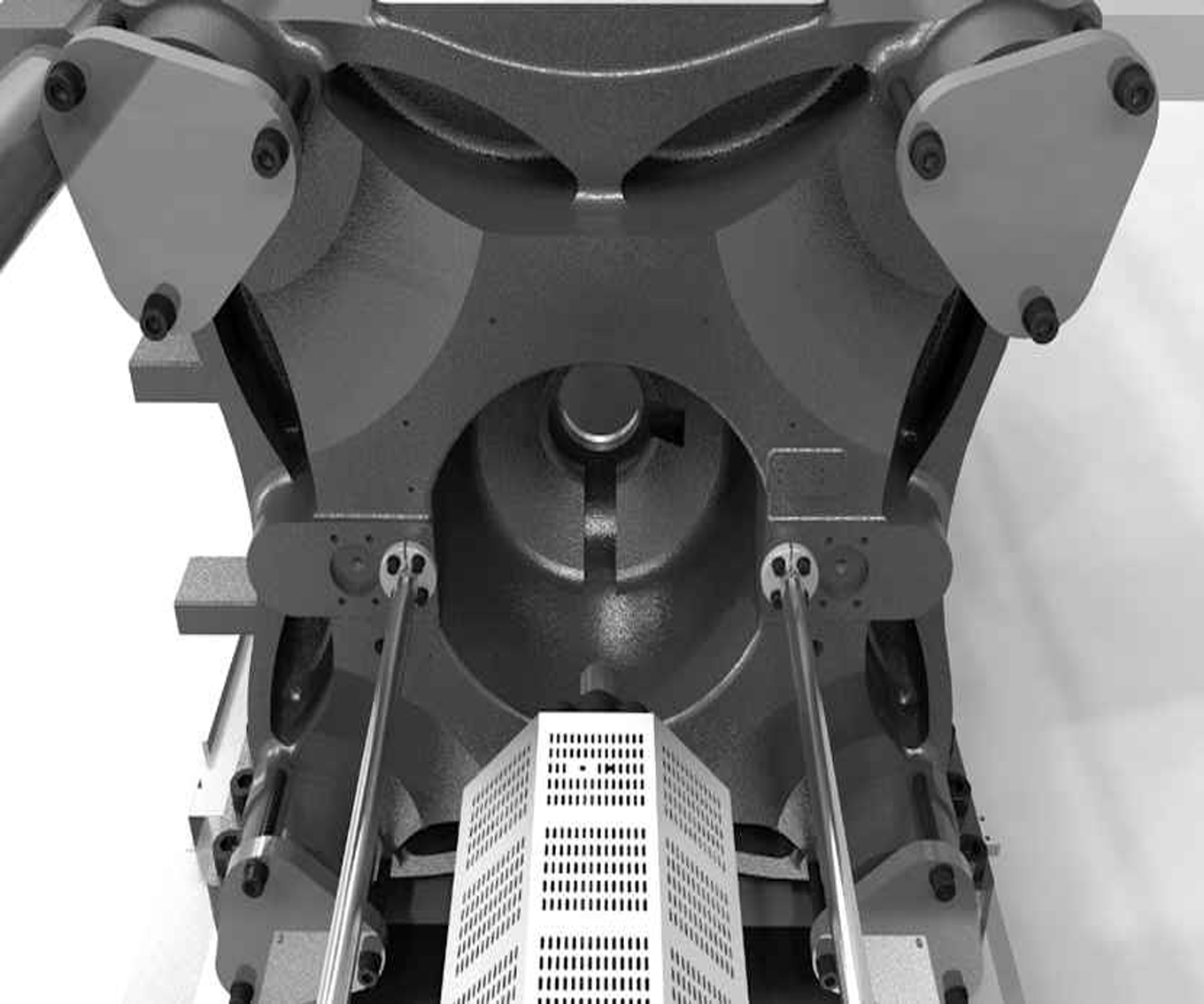

Automatic Mould Height Adjustment Unit

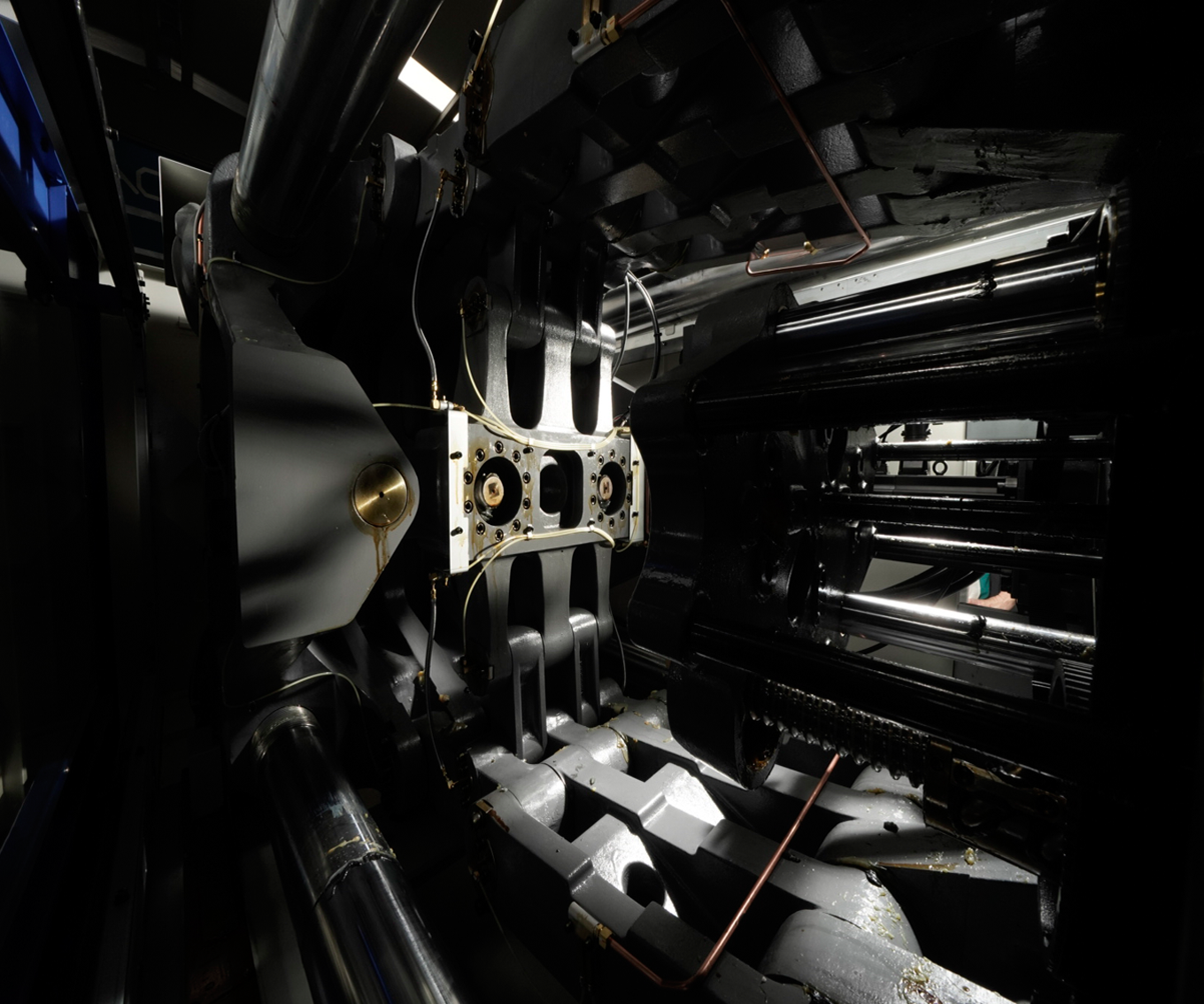

Hydraulic System

| SPECIFICATION | MG-168PET | |

|---|---|---|

| INJECTION UNIT | ||

| Screw Diameter | mm | 50 |

| Screw L/D Ratio | L/D | 20 |

| Short Size (Theoretical) | cm3 | 353 |

| Injection Weight(PET) | G | 458 |

| Injection Rate | g/s | 170 |

| Plasticizing Capacity | g/d | 25 |

| Injection Pressure | Mpa | 136 |

| Screw Speed | rpm | 0~150 |

| CLAMPING UNIT | ||

| Clamp Tonnage | KN | 1680 |

| Toggle Stroke | mm | 430 |

| Space Between Tie Bars | mm | 460×460 |

| Max. Mold Height | mm | 480 |

| Min. Mold Height | mm | 180 |

| Ejector Stroke | mm | 120 |

| Ejector Tonnage | KN | 40 |

| Ejector Number | Piece | 5 |

| OTHERS | ||

| Max. Pump Pressure | Mpa | 16 |

| pump motor Power | kw | 15 |

| Heater Power | kw | 13.00 |

| Machine Dimension(LxWxH) | M | 53×1.4×2.1 |

| Machine Weight | T | 5.2 |

| Hopper Capacity | kg | 25 |

| Oil Tank Capacity | L | 250 |

| SPECIFICATION | MG-398PET | |

|---|---|---|

| INJECTION UNIT | ||

| Screw Diameter | mm | 80 |

| Screw L/D Ratio | L/D | 21 |

| Short Size (Theoretical) | cm3 | 1689 |

| Injection Weight(PET) | G | 2195 |

| Injection Rate | g/s | 446 |

| Plasticizing Capacity | g/d | 70 |

| Injection Pressure | Mpa | 152 |

| Screw Speed | rpm | 0~165 |

| CLAMPING UNIT | ||

| Clamp Tonnage | KN | 3980 |

| Toggle Stroke | mm | 700 |

| Space Between Tie Bars | mm | 720×720 |

| Max. Mold Height | mm | 800 |

| Min. Mold Height | mm | 280 |

| Ejector Stroke | mm | 160 |

| Ejector Tonnage | KN | 110 |

| Ejector Number | Piece | 13 |

| OTHERS | ||

| Max. Pump Pressure | Mpa | 16 |

| pump motor Power | kw | 37 |

| Heater Power | kw | 26.2 |

| Machine Dimension(LxWxH) | M | 7.3×1.9×2.5 |

| Machine Weight | T | 15.7 |

| Hopper Capacity | kg | 50 |

| Oil Tank Capacity | L | 750 |

❖ Food and Beverage

❖ Automotive Parts

❖ Medical & Pharmaceuticals

❖ Household Products

❖ Agriculture

❖ Electronics

- Description

-

PLC Controller

PET Injection Unit

Clamping System

Automatic Mould Height Adjustment Unit

Hydraulic System

- Parameters

-

SPECIFICATION MG-168PET INJECTION UNIT Screw Diameter mm 50 Screw L/D Ratio L/D 20 Short Size (Theoretical) cm3 353 Injection Weight(PET) G 458 Injection Rate g/s 170 Plasticizing Capacity g/d 25 Injection Pressure Mpa 136 Screw Speed rpm 0~150 CLAMPING UNIT Clamp Tonnage KN 1680 Toggle Stroke mm 430 Space Between Tie Bars mm 460×460 Max. Mold Height mm 480 Min. Mold Height mm 180 Ejector Stroke mm 120 Ejector Tonnage KN 40 Ejector Number Piece 5 OTHERS Max. Pump Pressure Mpa 16 pump motor Power kw 15 Heater Power kw 13.00 Machine Dimension(LxWxH) M 53×1.4×2.1 Machine Weight T 5.2 Hopper Capacity kg 25 Oil Tank Capacity L 250 SPECIFICATION MG-398PET INJECTION UNIT Screw Diameter mm 80 Screw L/D Ratio L/D 21 Short Size (Theoretical) cm3 1689 Injection Weight(PET) G 2195 Injection Rate g/s 446 Plasticizing Capacity g/d 70 Injection Pressure Mpa 152 Screw Speed rpm 0~165 CLAMPING UNIT Clamp Tonnage KN 3980 Toggle Stroke mm 700 Space Between Tie Bars mm 720×720 Max. Mold Height mm 800 Min. Mold Height mm 280 Ejector Stroke mm 160 Ejector Tonnage KN 110 Ejector Number Piece 13 OTHERS Max. Pump Pressure Mpa 16 pump motor Power kw 37 Heater Power kw 26.2 Machine Dimension(LxWxH) M 7.3×1.9×2.5 Machine Weight T 15.7 Hopper Capacity kg 50 Oil Tank Capacity L 750 - Applications

-

❖ Food and Beverage

❖ Automotive Parts

❖ Medical & Pharmaceuticals

❖ Household Products

❖ Agriculture

❖ Electronics - Video

-